Page 311 - Introduction to chemical reaction engineering and kinetics

P. 311

292 Chapter 11: Preliminary Considerations in Chemical Reaction Engineering

indicated), and very strong chlorate liquor from the degasifier. The reactor produces

strong chlorate liquor (overflow to tank on the right), and feeds liquor to the electrolyz-

ers through an electrolyte cooler. No pumps are required to circulate liquor through the

reactor and electrolyzers. A high natural circulation rate (shown by the dashed line and

arrows) is established by the difference in density between the higher density liquid in

the reactor and the lower density liquid + gas (HZ) in the electrolyzer and riser. The

chlorate reactor contains an internal baffle to prevent short-circuiting of the circulating

liquor. The resulting liquid flow pattern in the reactor is nonideal, between BMF and

PF.

11.3 PROBLEMS FOR CHAPTER 11

11-1 For each of the examples shown in Figures 11.1 to 11.8, relate the features, as far as possible,

to the points listed in Section 11.1.1.2.

The following reactor problems illustrate some process calculations that involve material and/or

energy balances, and/or equilibrium considerations. They do not require rate considerations (or data)

involved with reactor sizing and product distribution, which are taken up in later chapters for these

same processes.

11-2 For a lOOO-tonne day-’ sulfuric acid plant (100% HzS04 basis), calculate the total molar flow

rate (mol s-l) of gas entering the SO2 converter (for oxidation to SO3), for steady-state oper-

ation, if the fractional conversion (fso,) in the converter is 0.98, and the feed to the converter

is 9.5 mol % SOZ. (1 tonne = 1000 kg.)

11-3 Calculate the (total) volumetric flow rate (m3 s-l> of gas leaving the reactor of a lOOO-tonne

day-’ ammonia plant, if the gas originates from Hz and N2 in the stoichiometric ratio, and

20% conversion to ammonia occurs. T = 45O”C, P = 300 bar, and the compressibility factor

z = 1.09. (1 tonne = 1000 kg.)

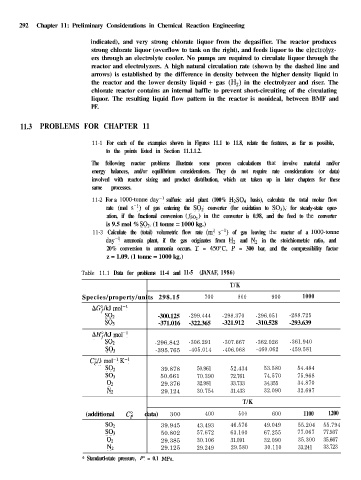

Table 11.1 Data for problems 11-4 and 11-5 (JANAF, 1986)

T/K

Species/property/units 298.15 700 800 900 1000

AG>/k.l mol-’

so2 -300.125 -299.444 -298.370 -296.051 -288.725

so3 -371.016 -322.365 -321.912 -310.528 -293.639

AH;/kJ mol-’

so2 -296.842 -306.291 -307.667 -362.026 -361.940

so3 -395.765 -405.014 -406.068 -460.062 -459.581

Ci/J mol-’ K-l

so2 39.878 50.961 52.434 53.580 54.484

so3 50.661 70.390 72.761 74.570 75.968

02 29.376 32.981 33.733 34.355 34.870

N2 29.124 30.754 31.433 32.090 32.697

T/K

(additional Ci data) 300 400 500 600 1100 1200

so2 39.945 43.493 46.576 49.049 55.204 55.794

so3 50.802 57.672 63.100 67.255 77.067 77.937

02 29.385 30.106 31.091 32.090 35.300 35.667

N 29.125 29.249 29.580 30.110 33.241 33.723

a Standard-state pressure, P” = 0.1 MPa.