Page 366 - Sami Franssila Introduction to Microfabrication

P. 366

Cleanrooms 345

taken into an airlock where the inner packing material 35.2 CLEANROOM SUBSYSTEMS

(which was wrapped in the cleanroom of wafer, target

35.2.1 Construction

or tool manufacturer) is removed. Depending on the

item, manual cleaning with isopropyl alcohol may

Cleanroom envelopes – walls, floor, ceiling, and so

be undertaken.

on – need to be made of materials compatible with the

As discussed in Chapter 34, cleanrooms need not

overall objective of environmental control. The walls

be large halls or rooms; mini-environments are locally

must not outgas, they must be easy to clean and they

clean areas around critical process tools. If wafers are

must be easily removable for equipment installation.

enclosed in portable mini-environments, they will never

They must also be tight because cleanliness is partly

experience cleanroom air, which can then be orders of

ensured by slight overpressure, which prevents outside

magnitude less clean, as shown in Figure 35.3.

air from entering. (In a virus research laboratory,

cleanliness must be achieved even though underpressure

must be applied in order to prevent samples from

escaping.) The ceiling consists of blank elements and

filter elements. The higher the proportion of filter

elements, the better the cleanroom class.

A raised, perforated floor is essential for unidirec-

tional (laminar) flow conditions: air from ceiling filters

can travel unidirectionally. If particles are generated in

Class 1 the cleanroom, they will be transported away directly

Class 10−100 through the floor, hopefully not interfering with the

wafers. Return air will travel laterally under the raised

Wafers floor, and return either in the service aisles or in separate

return air ducts. If service aisles are used as the return

path for the air, there will be turbulent upstream flow,

and even though the particle counts are low, the service

area is not suitable for wafer processing.

Tool Vibration isolation is important for lithography and

microscopy. Massive air-handling units generate vibra-

Raised floor tions, and therefore mechanical separation of air circula-

tion fans from other parts of the building is needed. Sen-

sitive process areas for lithography can be established on

(a) isolated concrete slabs extending down to bedrock.

Mini-environments

for tool and wafer 35.2.2 Air

transport

Air handling consists of four major blocks:

Class 1000−10000

Portable wafer • extraction unit

mini-environment • make-up air unit

Wafers • recirculation unit

Enclosed tools • filter fan units.

in mini-environment

class 0.1 In the first phase, the air is filtered from coarse

(b) objects, humidification or dehumidification is performed,

and airborne pollutants such as SO x , NO x and ammonia

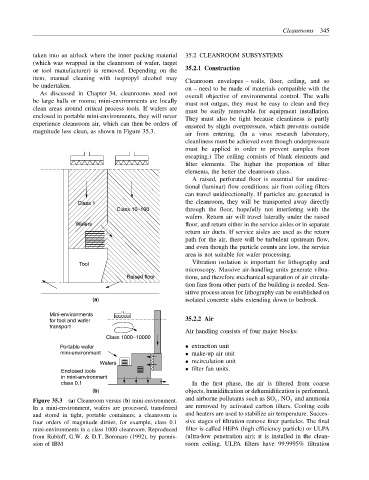

Figure 35.3 (a) Cleanroom versus (b) mini-environment.

In a mini-environment, wafers are processed, transferred are removed by activated carbon filters. Cooling coils

and stored in tight, portable containers; a cleanroom is and heaters are used to stabilize air temperature. Succes-

four orders of magnitude dirtier, for example, class 0.1 sive stages of filtration remove finer particles. The final

mini-environments in a class 1000 cleanroom. Reproduced filter is called HEPA (high efficiency particle) or ULPA

from Rubloff, G.W. & D.T. Boronaro (1992), by permis- (ultra-low penetration air); it is installed in the clean-

sion of IBM room ceiling. ULPA filters have 99.9995% filtration