Page 365 - Sami Franssila Introduction to Microfabrication

P. 365

344 Introduction to Microfabrication

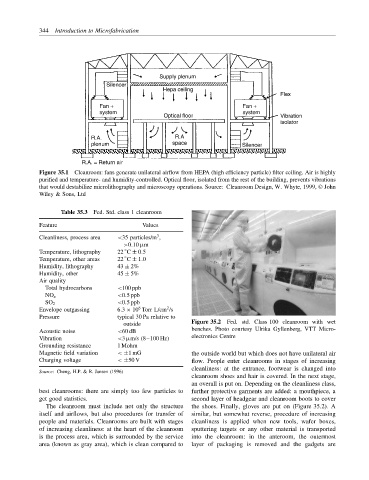

Supply plenum

Silencer

Hepa ceiling

Flex

Fan + Fan +

system system

Optical floor Vibration

isolator

R.A. R.A

plenum space Silencer

R.A. = Return air

Figure 35.1 Cleanroom: fans generate unilateral airflow from HEPA (high efficiency particle) filter ceiling. Air is highly

purified and temperature- and humidity-controlled. Optical floor, isolated from the rest of the building, prevents vibrations

that would destabilize microlithography and microscopy operations. Source: Cleanroom Design, W. Whyte, 1999, John

Wiley & Sons, Ltd

Table 35.3 Fed. Std. class 1 cleanroom

Feature Values

3

Cleanliness, process area <35 particles/m ,

>0.10 µm

◦

Temperature, lithography 22 C ± 0.5

Temperature, other areas 22 C ± 1.0

◦

Humidity, lithography 43 ± 2%

Humidity, other 45 ± 5%

Air quality

Total hydrocarbons <100 ppb

NO x <0.5 ppb

SO 2 <0.5 ppb

8

2

Envelope outgassing 6.3 × 10 Torr L/cm /s

Pressure typical 30 Pa relative to

outside Figure 35.2 Fed. std. Class 100 cleanroom with wet

Acoustic noise <60 dB benches. Photo courtesy Ulrika Gyllenberg, VTT Micro-

Vibration <3 µm/s (8–100 Hz) electronics Centre

Grounding resistance 1 Mohm

Magnetic field variation < ±1 mG the outside world but which does not have unilateral air

Charging voltage < ±50 V flow. People enter cleanrooms in stages of increasing

cleanliness: at the entrance, footwear is changed into

Source: Cheng, H.P. & R. Jansen (1996)

cleanroom shoes and hair is covered. In the next stage,

an overall is put on. Depending on the cleanliness class,

best cleanrooms: there are simply too few particles to further protective garments are added: a mouthpiece, a

get good statistics. second layer of headgear and cleanroom boots to cover

The cleanroom must include not only the structure the shoes. Finally, gloves are put on (Figure 35.2). A

itself and airflows, but also procedures for transfer of similar, but somewhat reverse, procedure of increasing

people and materials. Cleanrooms are built with stages cleanliness is applied when new tools, wafer boxes,

of increasing cleanliness: at the heart of the cleanroom sputtering targets or any other material is transported

is the process area, which is surrounded by the service into the cleanroom: in the anteroom, the outermost

area (known as gray area), which is clean compared to layer of packaging is removed and the gadgets are