Page 176 - Know and Understand Centrifugal Pumps

P. 176

Bearings

ENTRANCE

FORCED LUBE

RADIAL

BEARING

EXTERNAL

LUBE BOlTLE OIL LEVEL i\

INDICATOR

Figure 11-1 ~~

bearing failure, which leads to coupling and motor failure on the power

end, and mechanical seal failure on the wet end.

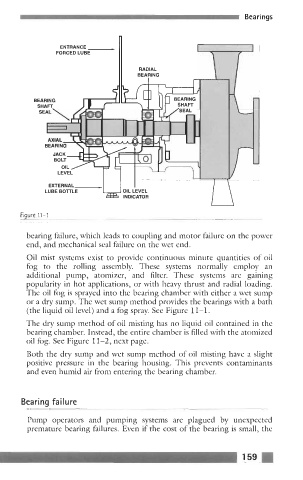

Oil mist systems exist to provide continuous minute quantities of oil

fog to the rolling assembly. These systems normally employ an

additional pump, atomizer, and filter. These systems are gaining

popularity in hot applications, or with heavy thrust and radial loading.

The oil fog is sprayed into the bearing chamber with either a wet sump

or a dry sump. The wet sump method provides the bearings with a bath

(the liquid oil level) and a fog spray. See Figure 1 1-1.

The dry sump method of oil misting has no liquid oil contained in the

bearing chamber. Instead, the entire chamber is filled with the atomized

oil fog. See Figure 11-2, next page.

Both the dry sump and wet sump method of oil misting have a slight

positive pressure in the bearing housing. This prevents contaminants

and even humid air from entering the bearing chamber.

Bearing failure

Pump operators and pumping systems are plagued by unexpected

premature bearing failures. Even if the cost of the bearing is small, the

159