Page 177 - Know and Understand Centrifugal Pumps

P. 177

Know and Understand Centrifugal Pumps

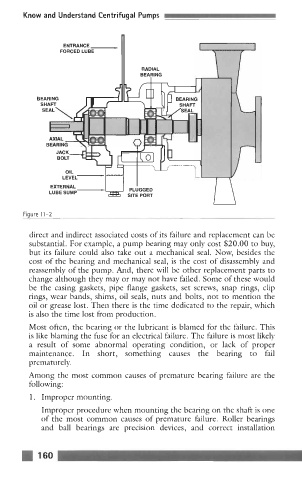

Fiaure 11-2

direct and indirect associated costs of its failure and replacement can be

substantial. For example, a pump bearing may only cost $20.00 to buy,

but its failure could also take out a mechanical seal. Now, besides the

cost of the bearing and mechanical seal, is the cost of disassembly and

reassembly of the pump. And, there will be other replacement parts to

change although they may or may not have failed. Some of these would

be the casing gaskets, pipe flange gaskets, set screws, snap rings, clip

rings, wear bands, shims, oil seals, nuts and bolts, not to mention the

oil or grease lost. Then there is the time dedicated to the repair, which

is also the time lost from production.

Most often, the bearing or the lubricant is blamed for the failure. This

is like blaming the hse for an electrical failure. The failure is most likely

a result of some abnormal operating condition, or lack of proper

maintenance. In short, something causes the bearing to fail

prematurely.

Among the most common causes of premature bearing failure are the

following:

1. Improper mounting.

Improper procedure when mounting the bearing on the shaft is one

of the most common causes of premature failure. Roller bearings

and ball bearings are precision devices, and correct installation

160