Page 182 - Know and Understand Centrifugal Pumps

P. 182

Bearings

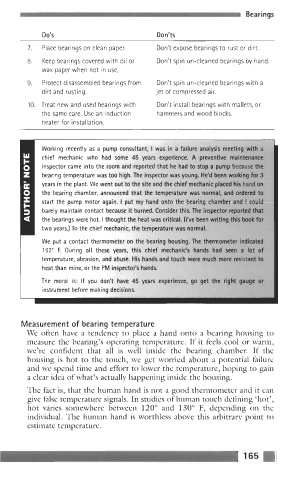

Do's Don'ts

7. Place bearings on clean paper. Don't expose bearings to rust or dirt.

8. Keep bearings covered with oil or Don't spin un-cleaned bearings by hand.

wax paper when not in use.

9. Protect disassembled bearings from Don't spin un-cleaned bearings with a

dirt and rusting. jet of compressed air.

IO. Treat new and used bearings with Don't install bearings with mallets, or

the same care. Use an induction hammers and wood blocks.

heater for installation.

Working recentlj y as a pump consultant, I was in a failure analysis meeting with a

chief mechanic who had some 45 years experi ence. A preventive maintenance

inspector came irllu lllc IUUIII d IIIU rcpttCU llldl llrf had to stop a pump because the

-4-

&L.- ---- --..I _----+,...I +Le& L.

bearing tempe rature was too hi gh. The inspector was young. He'd been working for 3

years in the pl, ant. We went out to the site and the chief mechanic placed his hand on

the bearing chamoer, announcc :d that the temperature was normal, and ordered to

.. .

.

.

start the pum p motor again. I put my hand 10 Into the bearing chamber and I could

barely maintai n contact because it burned. C :o t isider this. The inspector reported that

the bearings \n /ere hot. I thought the heat wa IS 1 critical. (I've been writinq this book for

two years.) To lllc LIIIcI IIlcI ~lldlllc, lllc lclllpcrature was normal

+ha nh:aC .ranL-r:n +ha +a-ns

We put a contact thermorr ieter on the bearing housing. The thermometer ir idicated

..

. . .

.

.

.

.

152" F. During all these years, this chief n nechanic's hands had seen a lot of

temperature, abr asion, and abuse. His hands ai id touch were much more resistant to

heat than mine, or the PM inspector's hands.

. .. . .-

The moral is: If you don't have 45 years ex :perience, go get the right gauge or

instruml ent before making decisions.

Measurement of bearing temperature

We ofien have a tendency to place a hand onto a bearing housing to

measure the bearing's operating temperature. If it feels cool or warm,

we're confident that all is well inside the bearing chamber. If the

housing is hot to the touch, we get worried about a potential failure

and we spend time and effort to lower the temperature, hoping to gain

a clear idea of what's actually happening inside the housing.

The fact is, that the human hand is not a good thermometer and it can

give false temperature signals. In studies of human touch defining 'hot',

hot varies somewhere between 120" and 130" F, depending on the

individual. The human hand is worthless above this arbitrary point to

estimate temperature.