Page 184 - Know and Understand Centrifugal Pumps

P. 184

Bearings

will be consistent with inadequate lubrication.

Sometimes bearings seem to run hot at pump start-up. This may be

heat actually generated by the bearing seals and not the bearings or

inadequate lubrication practices. After the seals seat and settle, the

temperature should go back to normal.

Bearing seals

The mechanical seal for bearings

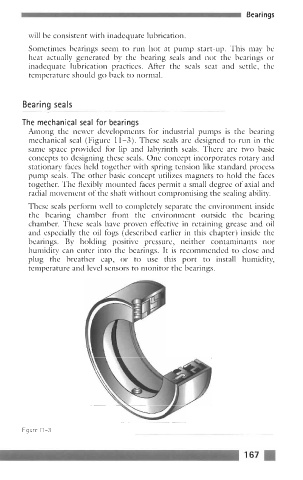

Among the newer developmcnts for industrial pumps is the bearing

mechanical seal (Figure 11-3). These seals are designed to run in the

same space provided for lip and labyrinth seals. There are two basic

concepts to designing these seals. One concept incorporates rotary and

stationary faces held together with spring tension like standard process

pump seals. The other basic concept utilizes magnets to hold the faces

together. The flexibly mounted faces permit a small degree of axial and

radial movement of the shaft without compromising the sealing ability.

These seals perform well to completely separate the environment inside

the bearing chamber from the environment outside the bearing

chamber. These seals have proven effective in retaining grease and oil

and especially the oil fogs (described earlier in this chapter) inside the

bearings. By holding positive pressure, neither contaminants nor

humidity can enter into the bearings. It is rccomrnended to close and

plug the breather cap, or to use this port to install humidity,

temperature and level sensors to monitor the bearings.

Figure 11-3

~

167 I