Page 277 - Lean six sigma demystified

P. 277

Chapter 8 Su S taining i mpr ovement 255

Results chart

15.0

UCL 14.49

14.0

13.0

CL 12.03 Results

UCL

12.0 +2 Sigma

Results Unstable conditions +1 Sigma

Average

11.0 –1 Sigma

–2 Sigma

LCL

10.0

LCL 9.57

9.0

8.0

123456789 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

Batch

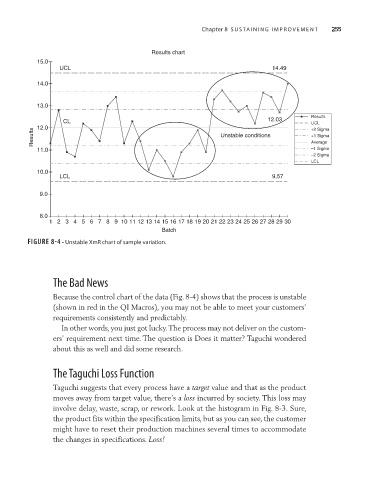

Figure 8-4 • Unstable XmR chart of sample variation.

The Bad News

Because the control chart of the data (Fig. 8-4) shows that the process is unstable

(shown in red in the QI Macros), you may not be able to meet your customers’

requirements consistently and predictably.

In other words, you just got lucky. The process may not deliver on the custom-

ers’ requirement next time. The question is Does it matter? Taguchi wondered

about this as well and did some research.

The Taguchi Loss Function

Taguchi suggests that every process have a target value and that as the product

moves away from target value, there’s a loss incurred by society. This loss may

involve delay, waste, scrap, or rework. Look at the histogram in Fig. 8-3. Sure,

the product fits within the specification limits, but as you can see, the customer

might have to reset their production machines several times to accommodate

the changes in specifications. Loss!