Page 113 - Materials Chemistry, Second Edition

P. 113

Life Cycle Assessment: Principles, Practice and Prospects

100

1 p

Reuse Feeder

Pump 100 kW

100%

720 kg 130 kg 42.5 kg 32 kg

Cast iron GG35 Steel (galvanised) Copper (primary; Aluminium

(IDEMAT) for wire) primary AU

26.8% 15.8% 16.3% 31.7%

350 kg 130 kg 32 kg

Steel cold rolled Aluminium

Oxysteel BOF primary AU

(BOF)

(disaggregated)

26.5% 13.3% 31.7%

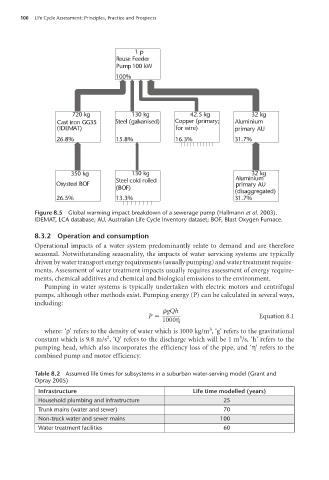

Figure 8.5 Global warming impact breakdown of a sewerage pump (Hallmann et al. 2003).

IDEMAT, LCA database; AU, Australian Life Cycle Inventory dataset; BOF, Blast Oxygen Furnace.

8.3.2 Operation and consumption

Operational impacts of a water system predominantly relate to demand and are therefore

seasonal. Notwithstanding seasonality, the impacts of water servicing systems are typically

driven by water transport energy requirements (usually pumping) and water treatment require-

ments. Assessment of water treatment impacts usually requires assessment of energy require-

ments, chemical additives and chemical and biological emissions to the environment.

Pumping in water systems is typically undertaken with electric motors and centrifugal

pumps, although other methods exist. Pumping energy (P) can be calculated in several ways,

including:

r gQh

P = Equation 8.1

1000h

3

where: ‘r’ refers to the density of water which is 1000 kg/m , ‘g’ refers to the gravitational

2

3

constant which is 9.8 m/s , ‘Q’ refers to the discharge which will be 1 m /s, ‘h’ refers to the

pumping head, which also incorporates the efficiency loss of the pipe, and ‘h’ refers to the

combined pump and motor efficiency.

Table 8.2 Assumed life times for subsystems in a suburban water-serving model (Grant and

Opray 2005)

Infrastructure Life time modelled (years)

Household plumbing and infrastructure 25

Trunk mains (water and sewer) 70

Non-truck water and sewer mains 100

Water treatment facilities 60

100804•Life Cycle Assessment 5pp.indd 100 17/02/09 12:46:20 PM