Page 259 - Lindens Handbook of Batteries

P. 259

MAGNeSiUM AND ALUMiNUM bATTerieS 10.11

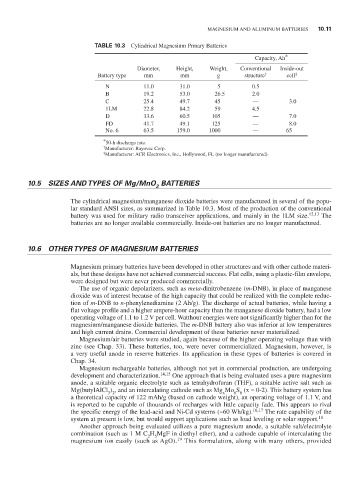

TABLE 10.3 Cylindrical Magnesium prmary batteries

Capacity, Ah *

Diameter, Height, Weight, Conventional inside-out

battery type mm mm g structure † cell ‡

N 11.0 31.0 5 0.5

b 19.2 53.0 26.5 2.0

C 25.4 49.7 45 — 3.0

1LM 22.8 84.2 59 4.5

D 33.6 60.5 105 — 7.0

FD 41.7 49.1 125 — 8.0

No. 6 63.5 159.0 1000 — 65

* 50-h discharge rate.

† Manufacturer: rayovac Corp.

‡ Manufacturer: ACr electronics, inc., Hollywood, FL (no longer manufactured).

10.5 SIZES AND TYPES OF Mg/MnO BATTERIES

2

The cylindrical magnesium/manganese dioxide batteries were manufactured in several of the popu-

lar standard ANSi sizes, as summarized in Table 10.3. Most of the production of the conventional

battery was used for military radio transceiver applications, and mainly in the 1LM size. 12,13 The

batteries are no longer available commercially. inside-out batteries are no longer manufactured.

10.6 OTHER TYPES OF MAGNESIUM BATTERIES

Magnesium primary batteries have been developed in other structures and with other cathode materi-

als, but these designs have not achieved commercial success. Flat cells, using a plastic-film envelope,

were designed but were never produced commercially.

The use of organic depolarizers, such as meta-dinitrobenzene (m-DNb), in place of manganese

dioxide was of interest because of the high capacity that could be realized with the complete reduc-

tion of m-DNb to n-phenylenediamine (2 Ah/g). The discharge of actual batteries, while having a

flat voltage profile and a higher ampere-hour capacity than the manganese dioxide battery, had a low

operating voltage of 1.1 to 1.2 V per cell. Watthour energies were not significantly higher than for the

magnesium/manganese dioxide batteries. The m-DNb battery also was inferior at low temperatures

and high current drains. Commercial development of these batteries never materialized.

Magnesium/air batteries were studied, again because of the higher operating voltage than with

zinc (see Chap. 33). These batteries, too, were never commercialized. Magnesium, however, is

a very useful anode in reserve batteries. its application in these types of batteries is covered in

Chap. 34.

Magnesium rechargeable batteries, although not yet in commercial production, are undergoing

development and characterization. 14,15 One approach that is being evaluated uses a pure magnesium

anode, a suitable organic electrolyte such as tetrahydrofuran (THF), a suitable active salt such as

Mg(butylAlCl ) , and an intercalating cathode such as Mg Mo S (x = 0-2). This battery system has

3 2

6 8

x

a theoretical capacity of 122 mAh/g (based on cathode weight), an operating voltage of 1.1 V, and

is reported to be capable of thousands of recharges with little capacity fade. This appears to rival

the specific energy of the lead-acid and Ni-Cd systems (~60 Wh/kg). 16,17 The rate capability of the

system at present is low, but would support applications such as load leveling or solar support. 18

Another approach being evaluated utilizes a pure magnesium anode, a suitable salt/electrolyte

combination (such as 1 M C H MgF in diethyl ether), and a cathode capable of intercalating the

2

5

magnesium ion easily (such as AgO). This formulation, along with many others, provided

19