Page 286 - Lindens Handbook of Batteries

P. 286

12.6 PRIMARY BATTERIES

Inner top

Outer top

Integrally molded

grommet

Adaptor tube Anode

Absorbent

Barrier

Inner can

Outer can Cathode

Vent

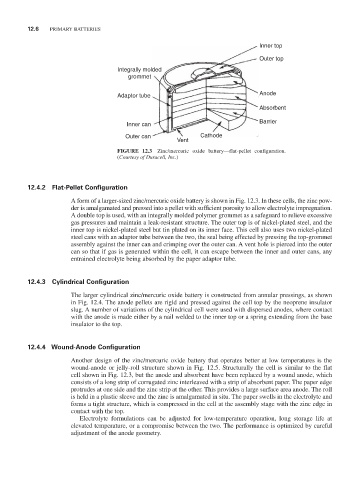

FIGURE 12.3 Zinc/mercuric oxide battery—flat-pellet configuration.

(Courtesy of Duracell, Inc.)

12.4.2 Flat-Pellet Configuration

A form of a larger-sized zinc/mercuric oxide battery is shown in Fig. 12.3. In these cells, the zinc pow-

der is amalgamated and pressed into a pellet with sufficient porosity to allow electrolyte impregnation.

A double top is used, with an integrally molded polymer grommet as a safeguard to relieve excessive

gas pressures and maintain a leak-resistant structure. The outer top is of nickel-plated steel, and the

inner top is nickel-plated steel but tin plated on its inner face. This cell also uses two nickel-plated

steel cans with an adaptor tube between the two, the seal being effected by pressing the top-grommet

assembly against the inner can and crimping over the outer can. A vent hole is pierced into the outer

can so that if gas is generated within the cell, it can escape between the inner and outer cans, any

entrained electrolyte being absorbed by the paper adaptor tube.

12.4.3 Cylindrical Configuration

The larger cylindrical zinc/mercuric oxide battery is constructed from annular pressings, as shown

in Fig. 12.4. The anode pellets are rigid and pressed against the cell top by the neoprene insulator

slug. A number of variations of the cylindrical cell were used with dispersed anodes, where contact

with the anode is made either by a nail welded to the inner top or a spring extending from the base

insulator to the top.

12.4.4 Wound-Anode Configuration

Another design of the zinc/mercuric oxide battery that operates better at low temperatures is the

wound-anode or jelly-roll structure shown in Fig. 12.5. Structurally the cell is similar to the flat

cell shown in Fig. 12.3, but the anode and absorbent have been replaced by a wound anode, which

consists of a long strip of corrugated zinc interleaved with a strip of absorbent paper. The paper edge

protrudes at one side and the zinc strip at the other. This provides a large surface area anode. The roll

is held in a plastic sleeve and the zinc is amalgamated in situ. The paper swells in the electrolyte and

forms a tight structure, which is compressed in the cell at the assembly stage with the zinc edge in

contact with the top.

Electrolyte formulations can be adjusted for low-temperature operation, long storage life at

elevated temperature, or a compromise between the two. The performance is optimized by careful

adjustment of the anode geometry.