Page 304 - Lindens Handbook of Batteries

P. 304

13.10 PrImArY BATTErIES

prevents migrating silver ions from reaching the anode 23,24 by reducing them to insoluble silver metal.

The cellophane is oxidized and destroyed in the process, making it less effective for long-life cells.

many types of laminated membranes are presently available. A commonly used alternate barrier

material is prepared from a radiation graft of methacrylic acid onto a polyethylene membrane. 23,24

The graft makes the film wettable and permeable to the electrolyte. Studies have shown that a lower

resistance polyethylene barrier membrane is suitable for high-rate KOH cells, while higher resis-

tance polyethylene is suitable for low-rate naOH cells. Cellophane is used in conjunction with the

grafted membrane as a sacrificial barrier. The lamination of cellophane to either side of the polyeth-

ylene membrane results in a synergistic action for stopping silver migration. 15

A separator is commonly used in conjunction with a barrier membrane layer as added protection

to the barrier. It is located between the barrier and anode cavity and is multifunctional both during

cell manufacture and in performance. Separators in zinc/silver cells are typically fibrous woven or

nonwoven polymers such as polyvinyl alcohol (PVA). The fibrous nature of the separator gives it

stability and strength that protects the more fragile barrier layers from compression failure during

cell closure or through penetration of zinc particles. The separator also acts to moderate the effects of

dimensional stresses in the barrier layers developed during the lamination processes. These stresses

are relieved as the barrier membranes wet up.

13.3 CONSTRUCTION

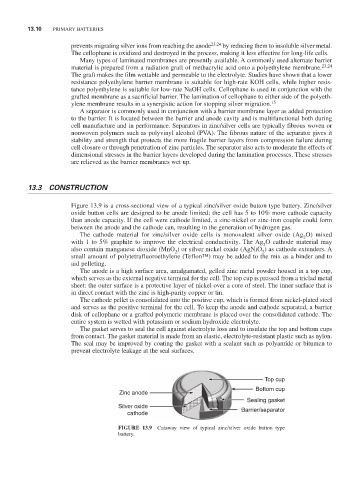

Figure 13.9 is a cross-sectional view of a typical zinc/silver oxide button type battery. Zinc/silver

oxide button cells are designed to be anode limited; the cell has 5 to 10% more cathode capacity

than anode capacity. If the cell were cathode limited, a zinc-nickel or zinc-iron couple could form

between the anode and the cathode can, resulting in the generation of hydrogen gas.

The cathode material for zinc/silver oxide cells is monovalent silver oxide (Ag O) mixed

2

with 1 to 5% graphite to improve the electrical conductivity. The Ag O cathode material may

2

also contain manganese dioxide (mnO ) or silver nickel oxide (AgniO ) as cathode extenders. A

2

2

small amount of polytetrafluoroethylene (Teflon™) may be added to the mix as a binder and to

aid pelleting.

The anode is a high surface area, amalgamated, gelled zinc metal powder housed in a top cup,

which serves as the external negative terminal for the cell. The top cup is pressed from a triclad metal

sheet: the outer surface is a protective layer of nickel over a core of steel. The inner surface that is

in direct contact with the zinc is high-purity copper or tin.

The cathode pellet is consolidated into the positive cup, which is formed from nickel-plated steel

and serves as the positive terminal for the cell. To keep the anode and cathode separated, a barrier

disk of cellophane or a grafted polymeric membrane is placed over the consolidated cathode. The

entire system is wetted with potassium or sodium hydroxide electrolyte.

The gasket serves to seal the cell against electrolyte loss and to insulate the top and bottom cups

from contact. The gasket material is made from an elastic, electrolyte-resistant plastic such as nylon.

The seal may be improved by coating the gasket with a sealant such as polyamide or bitumen to

prevent electrolyte leakage at the seal surfaces.

Top cup

Bottom cup

Zinc anode

Sealing gasket

Silver oxide Barrier/separator

cathode

FiGURE 13.9 Cutaway view of typical zinc/silver oxide button type

battery.