Page 299 - Lindens Handbook of Batteries

P. 299

BUTTOn CELL BATTErIES: SILVEr OxIDE–ZInC AnD ZInC-AIr SYSTEmS 13.5

1.8

A

1.7

1.6

B, C & D

1.5 E

Volume, V 1.4

1.3

C DEB A

1.2

1.1

1.0

10 20 30 40 50 60

Capacity (mAh) at 100k ohms continuous, 21°C

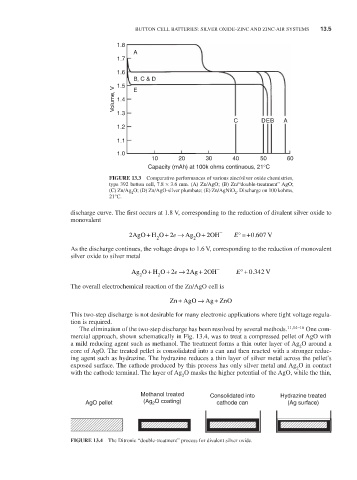

FiGURE 13.3 Comparative performances of various zinc/silver oxide chemistries,

type 392 button cell, 7.8 × 3.6 mm. (A) Zn/AgO; (B) Zn/“double-treatment” AgO;

(C) Zn/Ag O; (D) Zn/AgO-silver plumbate; (E) Zn/AgniO . Discharge on 100 kohms,

2

2

21°C.

discharge curve. The first occurs at 1.8 V, corresponding to the reduction of divalent silver oxide to

monovalent

+

2AgOH O + 2 2 → e AgO + 2 2OH - E° =+ 0 607 V

.

As the discharge continues, the voltage drops to 1.6 V, corresponding to the reduction of monovalent

silver oxide to silver metal

+

+

Ag OH O 2 → + e 2 Ag 2 OH - E° + 0 342 V

.

2

2

The overall electrochemical reaction of the Zn/AgO cell is

+

+

Zn AgO → AgZnO

This two-step discharge is not desirable for many electronic applications where tight voltage regula-

tion is required.

The elimination of the two-step discharge has been resolved by several methods. 11,14–16 One com-

mercial approach, shown schematically in Fig. 13.4, was to treat a compressed pellet of AgO with

a mild reducing agent such as methanol. The treatment forms a thin outer layer of Ag O around a

2

core of AgO. The treated pellet is consolidated into a can and then reacted with a stronger reduc-

ing agent such as hydrazine. The hydrazine reduces a thin layer of silver metal across the pellet’s

exposed surface. The cathode produced by this process has only silver metal and Ag O in contact

2

with the cathode terminal. The layer of Ag O masks the higher potential of the AgO, while the thin,

2

Methanol treated Consolidated into Hydrazine treated

AgO pellet (Ag 2 O coating) cathode can (Ag surface)

FiGURE 13.4 The Ditronic “double-treatment” process for divalent silver oxide.