Page 136 - Low Temperature Energy Systems with Applications of Renewable Energy

P. 136

Effective use of heat pumps for various heating applications 125

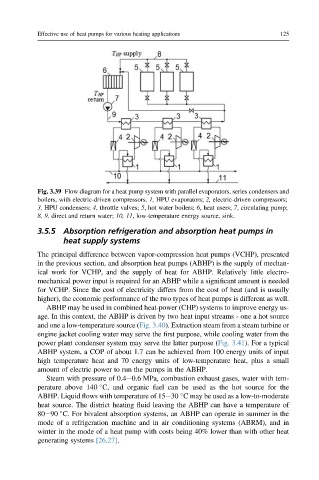

Fig. 3.39 Flow diagram for a heat pump system with parallel evaporators, series condensers and

boilers, with electric-driven compressors. 1, HPU evaporators; 2, electric-driven compressors;

3, HPU condensers; 4, throttle valves; 5, hot water boilers; 6, heat users; 7, circulating pump;

8, 9, direct and return water; 10, 11, low-temperature energy source, sink.

3.5.5 Absorption refrigeration and absorption heat pumps in

heat supply systems

The principal difference between vapor-compression heat pumps (VCHP), presented

in the previous section, and absorption heat pumps (ABHP) is the supply of mechan-

ical work for VCHP, and the supply of heat for ABHP. Relatively little electro-

mechanical power input is required for an ABHP while a significant amount is needed

for VCHP. Since the cost of electricity differs from the cost of heat (and is usually

higher), the economic performance of the two types of heat pumps is different as well.

ABHP may be used in combined heat-power (CHP) systems to improve energy us-

age. In this context, the ABHP is driven by two heat input streams - one a hot source

and one a low-temperature source (Fig. 3.40). Extraction steam from a steam turbine or

engine jacket cooling water may serve the first purpose, while cooling water from the

power plant condenser system may serve the latter purpose (Fig. 3.41). For a typical

ABHP system, a COP of about 1.7 can be achieved from 100 energy units of input

high temperature heat and 70 energy units of low-temperature heat, plus a small

amount of electric power to run the pumps in the ABHP.

Steam with pressure of 0.4e0.6 MPa, combustion exhaust gases, water with tem-

perature above 140 C, and organic fuel can be used as the hot source for the

ABHP. Liquid flows with temperature of 15e30 C may be used as a low-to-moderate

heat source. The district heating fluid leaving the ABHP can have a temperature of

80e90 C. For bivalent absorption systems, an ABHP can operate in summer in the

mode of a refrigeration machine and in air conditioning systems (ABRM), and in

winter in the mode of a heat pump with costs being 40% lower than with other heat

generating systems [26,27].