Page 71 - Low Temperature Energy Systems with Applications of Renewable Energy

P. 71

60 Low-Temperature Energy Systems with Applications of Renewable Energy

and nuclear power stations (NPSs), as well as large heat losses in (2) the heat distribu-

tion piping network [8].

The first loss (1) greatly influences environmental thermal pollution which may

contribute to global climate change. If energy consumption increases, this effect

may lead to a dangerous situation in the near future according to experts [8]. The

use of heat pumps that take advantage of power plant waste heat can mitigate this prob-

lem. In traditional heat supply systems, an amount of primary fuel is used to generate

the required amount of energy for the heating needs. In heat pumps a considerable part

of the useful thermal energy, 70e80%, is produced by low potential environmental

thermal energy.

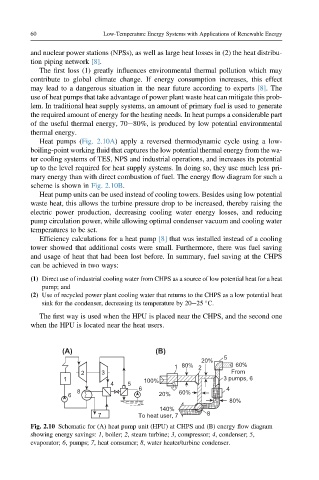

Heat pumps (Fig. 2.10A) apply a reversed thermodynamic cycle using a low-

boiling-point working fluid that captures the low potential thermal energy from the wa-

ter cooling systems of TES, NPS and industrial operations, and increases its potential

up to the level required for heat supply systems. In doing so, they use much less pri-

mary energy than with direct combustion of fuel. The energy flow diagram for such a

scheme is shown in Fig. 2.10B.

Heat pump units can be used instead of cooling towers. Besides using low potential

waste heat, this allows the turbine pressure drop to be increased, thereby raising the

electric power production, decreasing cooling water energy losses, and reducing

pump circulation power, while allowing optimal condenser vacuum and cooling water

temperatures to be set.

Efficiency calculations for a heat pump [8] that was installed instead of a cooling

tower showed that additional costs were small. Furthermore, there was fuel saving

and usage of heat that had been lost before. In summary, fuel saving at the CHPS

can be achieved in two ways:

(1) Direct use of industrial cooling water from CHPS as a source of low potential heat for a heat

pump; and

(2) Use of recycled power plant cooling water that returns to the CHPS as a low potential heat

sink for the condenser, decreasing its temperature by 20e25 C.

The first way is used when the HPU is placed near the CHPS, and the second one

when the HPU is located near the heat users.

(A) (B)

5

20%

1 80% 2 60%

2 3 From

1 100% 3 pumps, 6

4 5

6 4

8 60%

6 20%

80%

140%

7 To heat user, 7 8

Fig. 2.10 Schematic for (A) heat pump unit (HPU) at CHPS and (B) energy flow diagram

showing energy savings: 1, boiler; 2, steam turbine; 3, compressor; 4, condenser; 5,

evaporator; 6, pumps; 7, heat consumer; 8, water heater/turbine condenser.