Page 54 - MEMS Mechanical Sensors

P. 54

3.2 Simulation and Design Tools 43

PID controller

Output

−

8.2e 6 1.22e5 10e 6 −1.59e6

−

signal

1

1.0 1.0 −6

−

0v 0 1 + .3888e-3vs+72.9e 9vs*s

1/seismic 1 −10e −6 Gain of the Lowpass filter

0.5 mass Nonlinear

pick-off circuit −0.6

damping 2

VOCC 0

d

dt 0

0

12.3

83.3 Bias voltage

Parameters: 50

freq 0.5 Spring constant 1

1

2

2 −12.3

El.-st force generated −15 Bias voltage

by voltage on bottom plate

1 −50

2

15

El.-st force generated Saturation of drive amplifiers

by voltage on top plate

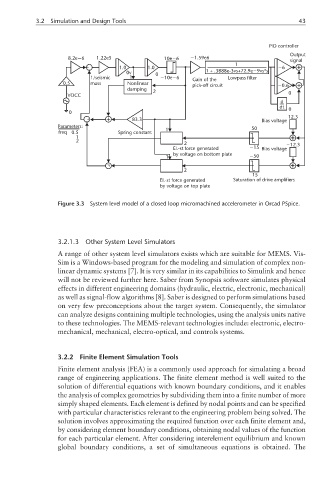

Figure 3.3 System level model of a closed loop micromachined accelerometer in Orcad PSpice.

3.2.1.3 Other System Level Simulators

A range of other system level simulators exists which are suitable for MEMS. Vis-

Sim is a Windows-based program for the modeling and simulation of complex non-

linear dynamic systems [7]. It is very similar in its capabilities to Simulink and hence

will not be reviewed further here. Saber from Synopsis software simulates physical

effects in different engineering domains (hydraulic, electric, electronic, mechanical)

as well as signal-flow algorithms [8]. Saber is designed to perform simulations based

on very few preconceptions about the target system. Consequently, the simulator

can analyze designs containing multiple technologies, using the analysis units native

to these technologies. The MEMS-relevant technologies include: electronic, electro-

mechanical, mechanical, electro-optical, and controls systems.

3.2.2 Finite Element Simulation Tools

Finite element analysis (FEA) is a commonly used approach for simulating a broad

range of engineering applications. The finite element method is well suited to the

solution of differential equations with known boundary conditions, and it enables

the analysis of complex geometries by subdividing them into a finite number of more

simply shaped elements. Each element is defined by nodal points and can be specified

with particular characteristics relevant to the engineering problem being solved. The

solution involves approximating the required function over each finite element and,

by considering element boundary conditions, obtaining nodal values of the function

for each particular element. After considering interelement equilibrium and known

global boundary conditions, a set of simultaneous equations is obtained. The