Page 51 - MEMS Mechanical Sensors

P. 51

40 MEMS Simulation and Design Tools

successfully applied to simulate electromagnetic fields, thermodynamic prob-

lems such as squeeze film damping, and fluidics. FEM results in more realistic

simulation results than behavioral modeling, but it is much more computa-

tionally demanding and hence it is difficult to simulate entire systems.

3.2 Simulation and Design Tools

3.2.1 Behavioral Modeling Simulation Tools

3.2.1.1 Matlab and Simulink

One of the most popular behavioral modeling tools is Simulink, which is a toolbox

within Matlab [1]. It allows the user to perform system level simulation in the time

domain. The user chooses blocks from a library that includes linear and nonlinear

functions, which are either time continuous or discrete. Examples include gain, inte-

grators and differentiators, z- and s-domain transfer functions, limiters, samplers,

mathematical functions, switches, and many others.

Each block has a range of input and outputs. An input can be the output of

another block or a source that can be an arbitrary waveform. Any output of a block

can be visualized by different types of plots in the time or frequency domain; alterna-

tively it can be stored as a variable to be analyzed or filtered further in Matlab. The

software allows user-defined library and hierarchal modeling by defining parame-

terized subsystems. The software has a purely graphical interface; blocks are chosen

by drag and drop and connected by wires drawn on the screen.

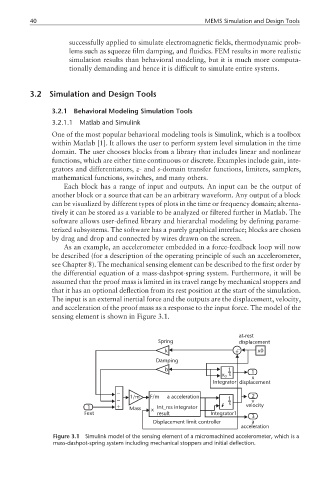

As an example, an accelerometer embedded in a force-feedback loop will now

be described (for a description of the operating principle of such an accelerometer,

see Chapter 8). The mechanical sensing element can be described to the first order by

the differential equation of a mass-dashpot-spring system. Furthermore, it will be

assumed that the proof mass is limited in its travel range by mechanical stoppers and

that it has an optional deflection from its rest position at the start of the simulation.

The input is an external inertial force and the outputs are the displacement, velocity,

and acceleration of the proof mass as a response to the input force. The model of the

sensing element is shown in Figure 3.1.

at-rest

Spring displacement

k x0

Damping

b 1

s 1

x o

x

Integrator displacement

− 1/m F/m a acceleration 2

− 1 v

1 + Mass x Int_res integrator s velocity

Fext result Integrator1

3

Displacement limit controller a

acceleration

Figure 3.1 Simulink model of the sensing element of a micromachined accelerometer, which is a

mass-dashpot-spring system including mechanical stoppers and initial deflection.