Page 52 - MEMS Mechanical Sensors

P. 52

3.2 Simulation and Design Tools 41

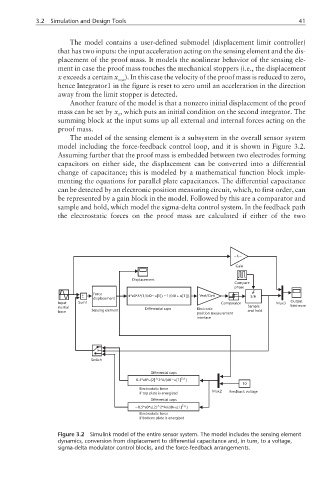

The model contains a user-defined submodel (displacement limit controller)

that has two inputs: the input acceleration acting on the sensing element and the dis-

placement of the proof mass. It models the nonlinear behavior of the sensing ele-

ment in case the proof mass touches the mechanical stoppers (i.e., the displacement

x exceeds a certain x ). In this case the velocity of the proof mass is reduced to zero,

max

hence Integrator1 in the figure is reset to zero until an acceleration in the direction

away from the limit stopper is detected.

Another feature of the model is that a nonzero initial displacement of the proof

mass can be set by x , which puts an initial condition on the second integrator. The

0

summing block at the input sums up all external and internal forces acting on the

proof mass.

The model of the sensing element is a subsystem in the overall sensor system

model including the force-feedback control loop, and it is shown in Figure 3.2.

Assuming further that the proof mass is embedded between two electrodes forming

capacitors on either side, the displacement can be converted into a differential

change of capacitance; this is modeled by a mathematical function block imple-

menting the equations for parallel plate capacitances. The differential capacitance

can be detected by an electronic position measuring circuit, which, to first order, can

be represented by a gain block in the model. Followed by this are a comparator and

sample and hold, which model the sigma-delta control system. In the feedback path

the electrostatic forces on the proof mass are calculated if either of the two

−−

K

Gain

Displacement

Compare

phase

+ Force 4*e0*A*(1/(d0 u[1]) − 1/(d0 + u[1])) Vext/Cint

−

− displacement S/H

Input Sum1 Comparator Mux3 Output

inertial Differential caps Electronic Sample bitstream

force Sensing element and hold

position measurement

interface

Switch

Differential caps

∧

0.5*e0*u[2] 2*A/(d0 u[1] ∧ )

2

−

10

Electrostatic force

if top plate is energized Mux2 Feedback voltage

Differential caps

−0.5*e0*u[2] 2*A/(d0+u[1] ∧ )

∧

2

Electrostatic force

if bottom plate is energized

Figure 3.2 Simulink model of the entire sensor system. The model includes the sensing element

dynamics, conversion from displacement to differential capacitance and, in turn, to a voltage,

sigma-delta modulator control blocks, and the force-feedback arrangements.