Page 47 - MEMS Mechanical Sensors

P. 47

36 Materials and Fabrication Techniques

Potentiostat

I=0

+ −

electrode electrode

n-Si Counter Reference

p-Si Etchant

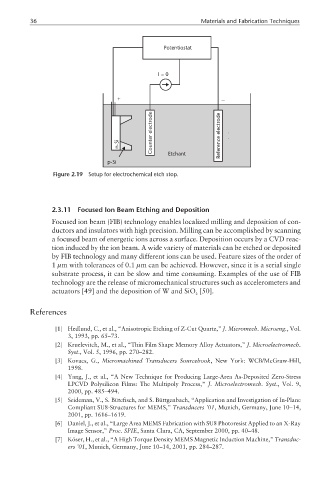

Figure 2.19 Setup for electrochemical etch stop.

2.3.11 Focused Ion Beam Etching and Deposition

Focused ion beam (FIB) technology enables localized milling and deposition of con-

ductors and insulators with high precision. Milling can be accomplished by scanning

a focused beam of energetic ions across a surface. Deposition occurs by a CVD reac-

tion induced by the ion beam. A wide variety of materials can be etched or deposited

by FIB technology and many different ions can be used. Feature sizes of the order of

1 µm with tolerances of 0.1 µm can be achieved. However, since it is a serial single

substrate process, it can be slow and time consuming. Examples of the use of FIB

technology are the release of micromechanical structures such as accelerometers and

actuators [49] and the deposition of W and SiO [50].

2

References

[1] Hedlund, C., et al., “Anisotropic Etching of Z-Cut Quartz,” J. Micromech. Microeng., Vol.

3, 1993, pp. 65–73.

[2] Kruelevitch, M., et al., “Thin Film Shape Memory Alloy Actuators,” J. Microelectromech.

Syst., Vol. 5, 1996, pp. 270–282.

[3] Kovacs, G., Micromachined Transducers Sourcebook, New York: WCB/McGraw-Hill,

1998.

[4] Yang, J., et al., “A New Technique for Producing Large-Area As-Deposited Zero-Stress

LPCVD Polysilicon Films: The Multipoly Process,” J. Microelectromech. Syst., Vol. 9,

2000, pp. 485–494.

[5] Seideman, V., S. Bütefisch, and S. Büttgenbach, “Application and Investigation of In-Plane

Compliant SU8-Structures for MEMS,” Transducers ’01, Munich, Germany, June 10–14,

2001, pp. 1616–1619.

[6] Daniel, J., et al., “Large Area MEMS Fabrication with SU8 Photoresist Applied to an X-Ray

Image Sensor,” Proc. SPIE, Santa Clara, CA, September 2000, pp. 40–48.

[7] Köser, H., et al., “A High Torque Density MEMS Magnetic Induction Machine,” Transduc-

ers ’01, Munich, Germany, June 10–14, 2001, pp. 284–287.