Page 293 - MEMS and Microstructures in Aerospace Applications

P. 293

Osiander / MEMS and microstructures in Aerospace applications DK3181_c012 Final Proof page 285 1.9.2005 9:13pm

MEMS Packaging for Space Applications 285

68 mm DIA

Sensor

head

Microchannel plate

Housing

Anode plate

75 mm

PC board

High voltage

Power supply

91 mm

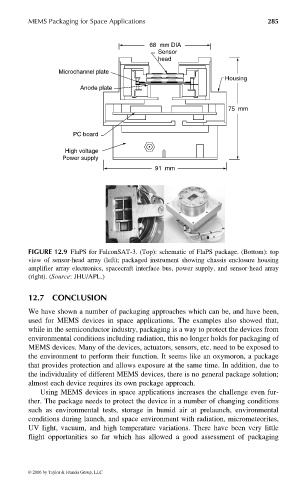

FIGURE 12.9 FlaPS for FalconSAT-3. (Top): schematic of FlaPS package. (Bottom): top

view of sensor-head array (left); packaged instrument showing chassis enclosure housing

amplifier array electronics, spacecraft interface bus, power supply, and sensor-head array

(right). (Source: JHU/APL.)

12.7 CONCLUSION

We have shown a number of packaging approaches which can be, and have been,

used for MEMS devices in space applications. The examples also showed that,

while in the semiconductor industry, packaging is a way to protect the devices from

environmental conditions including radiation, this no longer holds for packaging of

MEMS devices. Many of the devices, actuators, sensors, etc. need to be exposed to

the environment to perform their function. It seems like an oxymoron, a package

that provides protection and allows exposure at the same time. In addition, due to

the individuality of different MEMS devices, there is no general package solution;

almost each device requires its own package approach.

Using MEMS devices in space applications increases the challenge even fur-

ther. The package needs to protect the device in a number of changing conditions

such as environmental tests, storage in humid air at prelaunch, environmental

conditions during launch, and space environment with radiation, micrometeorites,

UV light, vacuum, and high temperature variations. There have been very little

flight opportunities so far which has allowed a good assessment of packaging

© 2006 by Taylor & Francis Group, LLC