Page 345 - MEMS and Microstructures in Aerospace Applications

P. 345

Osiander / MEMS and microstructures in Aerospace applications DK3181_c015 Final Proof page 338 1.9.2005 12:52pm

338 MEMS and Microstructures in Aerospace Applications

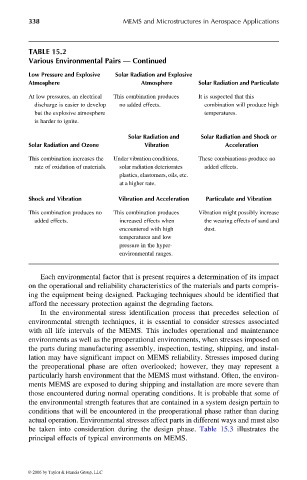

TABLE 15.2

Various Environmental Pairs — Continued

Low Pressure and Explosive Solar Radiation and Explosive

Atmosphere Atmosphere Solar Radiation and Particulate

At low pressures, an electrical This combination produces It is suspected that this

discharge is easier to develop no added effects. combination will produce high

but the explosive atmosphere temperatures.

is harder to ignite.

Solar Radiation and Solar Radiation and Shock or

Solar Radiation and Ozone Vibration Acceleration

This combination increases the Under vibration conditions, These combinations produce no

rate of oxidation of materials. solar radiation deteriorates added effects.

plastics, elastomers, oils, etc.

at a higher rate.

Shock and Vibration Vibration and Acceleration Particulate and Vibration

This combination produces no This combination produces Vibration might possibly increase

added effects. increased effects when the wearing effects of sand and

encountered with high dust.

temperatures and low

pressure in the hyper-

environmental ranges.

Each environmental factor that is present requires a determination of its impact

on the operational and reliability characteristics of the materials and parts compris-

ing the equipment being designed. Packaging techniques should be identified that

afford the necessary protection against the degrading factors.

In the environmental stress identification process that precedes selection of

environmental strength techniques, it is essential to consider stresses associated

with all life intervals of the MEMS. This includes operational and maintenance

environments as well as the preoperational environments, when stresses imposed on

the parts during manufacturing assembly, inspection, testing, shipping, and instal-

lation may have significant impact on MEMS reliability. Stresses imposed during

the preoperational phase are often overlooked; however, they may represent a

particularly harsh environment that the MEMS must withstand. Often, the environ-

ments MEMS are exposed to during shipping and installation are more severe than

those encountered during normal operating conditions. It is probable that some of

the environmental strength features that are contained in a system design pertain to

conditions that will be encountered in the preoperational phase rather than during

actual operation. Environmental stresses affect parts in different ways and must also

be taken into consideration during the design phase. Table 15.3 illustrates the

principal effects of typical environments on MEMS.

© 2006 by Taylor & Francis Group, LLC