Page 348 - MEMS and Microstructures in Aerospace Applications

P. 348

Osiander / MEMS and microstructures in Aerospace applications DK3181_c015 Final Proof page 341 1.9.2005 12:53pm

Design and Application of Space-Based MEMS 341

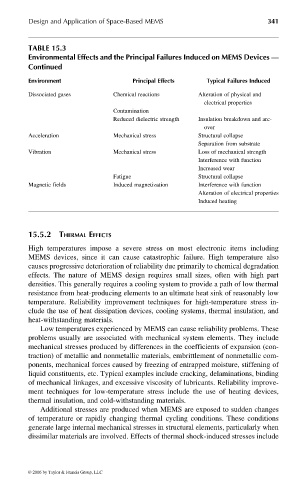

TABLE 15.3

Environmental Effects and the Principal Failures Induced on MEMS Devices —

Continued

Environment Principal Effects Typical Failures Induced

Dissociated gases Chemical reactions Alteration of physical and

electrical properties

Contamination

Reduced dielectric strength Insulation breakdown and arc-

over

Acceleration Mechanical stress Structural collapse

Separation from substrate

Vibration Mechanical stress Loss of mechanical strength

Interference with function

Increased wear

Fatigue Structural collapse

Magnetic fields Induced magnetization Interference with function

Alteration of electrical properties

Induced heating

15.5.2 THERMAL EFFECTS

High temperatures impose a severe stress on most electronic items including

MEMS devices, since it can cause catastrophic failure. High temperature also

causes progressive deterioration of reliability due primarily to chemical degradation

effects. The nature of MEMS design requires small sizes, often with high part

densities. This generally requires a cooling system to provide a path of low thermal

resistance from heat-producing elements to an ultimate heat sink of reasonably low

temperature. Reliability improvement techniques for high-temperature stress in-

clude the use of heat dissipation devices, cooling systems, thermal insulation, and

heat-withstanding materials.

Low temperatures experienced by MEMS can cause reliability problems. These

problems usually are associated with mechanical system elements. They include

mechanical stresses produced by differences in the coefficients of expansion (con-

traction) of metallic and nonmetallic materials, embrittlement of nonmetallic com-

ponents, mechanical forces caused by freezing of entrapped moisture, stiffening of

liquid constituents, etc. Typical examples include cracking, delaminations, binding

of mechanical linkages, and excessive viscosity of lubricants. Reliability improve-

ment techniques for low-temperature stress include the use of heating devices,

thermal insulation, and cold-withstanding materials.

Additional stresses are produced when MEMS are exposed to sudden changes

of temperature or rapidly changing thermal cycling conditions. These conditions

generate large internal mechanical stresses in structural elements, particularly when

dissimilar materials are involved. Effects of thermal shock-induced stresses include

© 2006 by Taylor & Francis Group, LLC