Page 361 - MEMS and Microstructures in Aerospace Applications

P. 361

Osiander / MEMS and microstructures in Aerospace applications DK3181_c016 Final Proof page 354 1.9.2005 12:56pm

354 MEMS and Microstructures in Aerospace Applications

Post release Gross leak test

device receipt MIL-STD-883 Method 1014

Condition C

Precap visual inspection

MIL-STD-883 Method 2010 Interim electricals at

Condition A or 25 C DC

(Hybrid Method 2017)

Burn-in test

Packaging and sealing MIL-STD-883 Method 1015

160 Hrs @ 125 C

Final electrical test

Stabilization bake

MIL-STD-883 Method 1008 + 25 C, +125 C, −55 C DC

Condition C

(Includes functional tests)

+ 25 C AC

Temperature cycling

MIL-STD-883 Method 1010

Condition C External visual

MIL-STD-883 Method 2009

Constant acceleration

MIL-STD-883 Method 2001

Condition E (Y1 Only) Move to next higher

integration step

Fine leak test

MIL-STD-883 Method 1014

Condition B

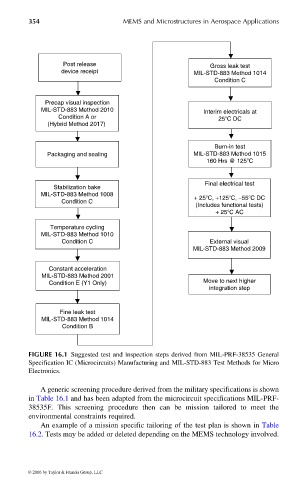

FIGURE 16.1 Suggested test and inspection steps derived from MIL-PRF-38535 General

Specification IC (Microcircuits) Manufacturing and MIL-STD-883 Test Methods for Micro

Electronics.

A generic screening procedure derived from the military specifications is shown

in Table 16.1 and has been adapted from the microcircuit specifications MIL-PRF-

38535F. This screening procedure then can be mission tailored to meet the

environmental constraints required.

An example of a mission specific tailoring of the test plan is shown in Table

16.2. Tests may be added or deleted depending on the MEMS technology involved.

© 2006 by Taylor & Francis Group, LLC