Page 149 - Machinery Component Maintenance

P. 149

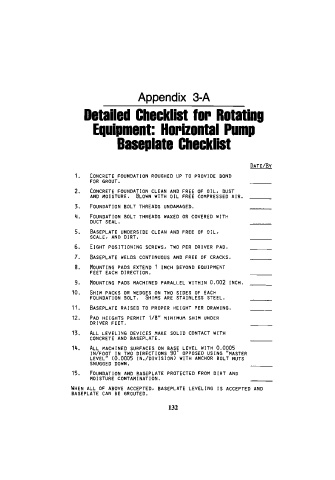

Appendix 3-A

Detailed Checklist for Rotating

Equipment: Horizontal Pump

Baseplate Checklist

DATE/BY

1. CONCRETE FOUNDATION ROUGHED UP TO PROVIDE BOND

FOR GROUT.

2. CONCRETE FOUNDATION CLEAN AND FREE OF OIL. DUST

AND MOISTURE. BLOWN WITH OIL FREE COMPRESSED AIR.

3. FOUNDATION BOLT THREADS UNDAMAGED.

4. FOUNDATION BOLT THREADS WAXED OR COVERED WITH

DUCT SEAL.

5. BASEPLATE UNDERSIDE CLEAN AND FREE OF OIL,

SCALE. AND DIRT.

6. EIGHT POSITIONING SCREWS, TWO PER DRIVER PAD.

7. BASEPLATE WELDS CONTINUOUS AND FREE OF CRACKS.

8. MOUNTING PADS EXTEND 1 INCH BEYOND EQUIPMENT

FEET EACH DIRECTION.

9. MOUNTING PADS MACHINED PARALLEL WITHIN 0.002 INCH.

10. SHIM PACKS OR WEDGES ON TWO SIDES OF EACH

FOUNDATION BOLT. SHIMS ARE STAINLESS STEEL.

11. BASEPLATE RAISED TO PROPER HEIGHT PER DRAWING.

PAD HEIGHTS PERMIT 1/8" MINIMUM SHIM UNDER

12 I

DRIVER FEET.

13. ALL LEVELING DEVICES MAKE SOLID CONTACT WITH

CONCRETE AND BASEPLATE.

14. ALL MACHINED SURFACES ON BASE LEVEL WITH 0.0005

IN/FO;T IN TWO DIRECTIONS 90' OPPOSED USING "MASTER

LEVEL (0.0005 IN./DIVISION) WITH ANCHOR BOLT NUTS

SNUGGED DOWN I

15. FOUNDATION AND BASEPLATE PROTECTED FROM DIRT AND

MOISTURE CONTAMINATION.

WHEN ALL OF ABOVE ACCEPTED. BASEPLATE LEVELING IS ACCEPTED AND

BASEPLATE CAN BE GROUTED.

132