Page 331 - Machinery Component Maintenance

P. 331

Balancing of Machinery Components 313

Bearing or journal changes.

Environmental differences (heat, humidity).

l Shipping or handling damage.

Aging or stress relieving of components.

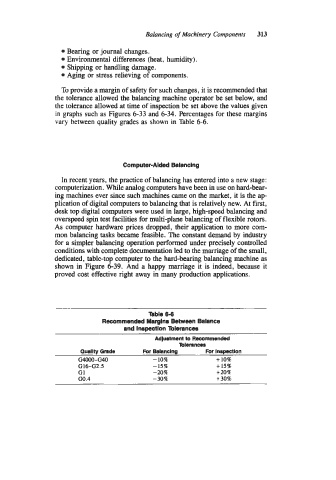

To provide a margin of safety for such changes, it is recommended that

the tolerance allowed the balancing machine operator be set below, and

the tolerance allowed at time of inspection be set above the values given

in graphs such as Figures 6-33 and 6-34. Percentages for these margins

vary between quality grades as shown in Table 6-6.

Computer-Aided Balancing

In recent years, the practice of balancing has entered into a new stage:

computerization. While analog computers have been in use on hard-bear-

ing machines ever since such machines came on the market, it is the ap-

plication of digital computers to balancing that is relatively new. At first,

desk top digital computers were used in large, high-speed balancing and

overspeed spin test facilities for multi-plane balancing of flexible rotors.

As computer hardware prices dropped, their application to more com-

mon balancing tasks became feasible. The constant demand by industry

for a simpler balancing operation performed under precisely controlled

conditions with complete documentation led to the marriage of the small,

dedicated, table-top computer to the hard-bearing balancing machine as

shown in Figure 6-39. And a happy marriage it is indeed, because it

proved cost effective right away in many production applications.

Tgble 6-6

Recommended Margins Between Balance

and Insmction Tolerances

Adjustment to Recommended

Tolerances

Quality Grade For Balancing For Inspection

G4000-G40 - 10% + 10%

G 16-G2.5 - 15% + 15%

GI -20% t 20%

Go.4 -302 t 30%