Page 167 - Make Your Own PCBs with EAGLE from Schematic Designs to Finished Boards

P. 167

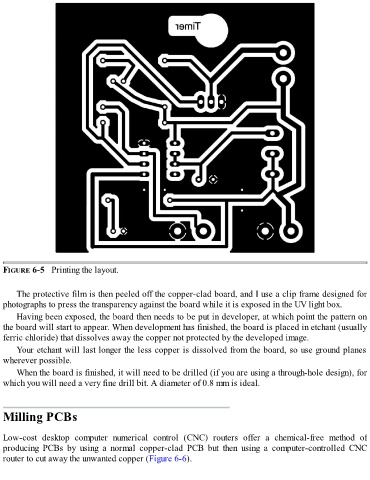

FIGURE 6-5 Printing the layout.

The protective film is then peeled off the copper-clad board, and I use a clip frame designed for

photographs to press the transparency against the board while it is exposed in the UV light box.

Having been exposed, the board then needs to be put in developer, at which point the pattern on

the board will start to appear. When development has finished, the board is placed in etchant (usually

ferric chloride) that dissolves away the copper not protected by the developed image.

Your etchant will last longer the less copper is dissolved from the board, so use ground planes

wherever possible.

When the board is finished, it will need to be drilled (if you are using a through-hole design), for

which you will need a very fine drill bit. A diameter of 0.8 mm is ideal.

Milling PCBs

Low-cost desktop computer numerical control (CNC) routers offer a chemical-free method of

producing PCBs by using a normal copper-clad PCB but then using a computer-controlled CNC

router to cut away the unwanted copper (Figure 6-6).