Page 18 - Make Your Own PCBs with EAGLE from Schematic Designs to Finished Boards

P. 18

pins that are just 0.5 mm apart. Although many SMDs are easy enough to solder by hand, many others

are just too small.

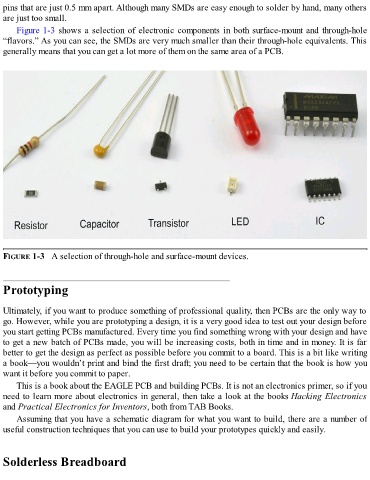

Figure 1-3 shows a selection of electronic components in both surface-mount and through-hole

“flavors.” As you can see, the SMDs are very much smaller than their through-hole equivalents. This

generally means that you can get a lot more of them on the same area of a PCB.

FIGURE 1-3 A selection of through-hole and surface-mount devices.

Prototyping

Ultimately, if you want to produce something of professional quality, then PCBs are the only way to

go. However, while you are prototyping a design, it is a very good idea to test out your design before

you start getting PCBs manufactured. Every time you find something wrong with your design and have

to get a new batch of PCBs made, you will be increasing costs, both in time and in money. It is far

better to get the design as perfect as possible before you commit to a board. This is a bit like writing

a book—you wouldn’t print and bind the first draft; you need to be certain that the book is how you

want it before you commit to paper.

This is a book about the EAGLE PCB and building PCBs. It is not an electronics primer, so if you

need to learn more about electronics in general, then take a look at the books Hacking Electronics

and Practical Electronics for Inventors, both from TAB Books.

Assuming that you have a schematic diagram for what you want to build, there are a number of

useful construction techniques that you can use to build your prototypes quickly and easily.

Solderless Breadboard