Page 21 - Make Your Own PCBs with EAGLE from Schematic Designs to Finished Boards

P. 21

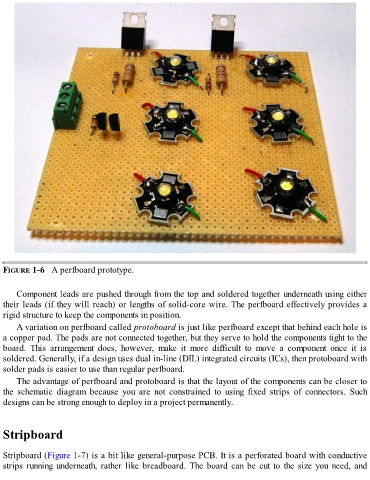

FIGURE 1-6 A perfboard prototype.

Component leads are pushed through from the top and soldered together underneath using either

their leads (if they will reach) or lengths of solid-core wire. The perfboard effectively provides a

rigid structure to keep the components in position.

A variation on perfboard called protoboard is just like perfboard except that behind each hole is

a copper pad. The pads are not connected together, but they serve to hold the components tight to the

board. This arrangement does, however, make it more difficult to move a component once it is

soldered. Generally, if a design uses dual in-line (DIL) integrated circuits (ICs), then protoboard with

solder pads is easier to use than regular perfboard.

The advantage of perfboard and protoboard is that the layout of the components can be closer to

the schematic diagram because you are not constrained to using fixed strips of connectors. Such

designs can be strong enough to deploy in a project permanently.

Stripboard

Stripboard (Figure 1-7) is a bit like general-purpose PCB. It is a perforated board with conductive

strips running underneath, rather like breadboard. The board can be cut to the size you need, and