Page 19 - Make Your Own PCBs with EAGLE from Schematic Designs to Finished Boards

P. 19

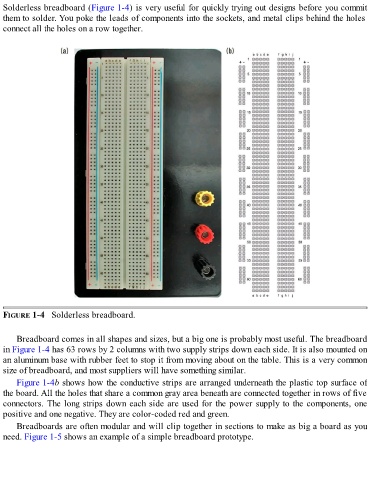

Solderless breadboard (Figure 1-4) is very useful for quickly trying out designs before you commit

them to solder. You poke the leads of components into the sockets, and metal clips behind the holes

connect all the holes on a row together.

FIGURE 1-4 Solderless breadboard.

Breadboard comes in all shapes and sizes, but a big one is probably most useful. The breadboard

in Figure 1-4 has 63 rows by 2 columns with two supply strips down each side. It is also mounted on

an aluminum base with rubber feet to stop it from moving about on the table. This is a very common

size of breadboard, and most suppliers will have something similar.

Figure 1-4b shows how the conductive strips are arranged underneath the plastic top surface of

the board. All the holes that share a common gray area beneath are connected together in rows of five

connectors. The long strips down each side are used for the power supply to the components, one

positive and one negative. They are color-coded red and green.

Breadboards are often modular and will clip together in sections to make as big a board as you

need. Figure 1-5 shows an example of a simple breadboard prototype.