Page 134 - Manufacturing Engineering and Technology - Kalpakjian, Serope : Schmid, Steven R.

P. 134

I 10 Heat Treatment of Ferrous Alloys I I3

,jjj p ;

gy,,,.f .

. ri , H

Section 4.7

.fy

_

70

if 3

2

TZ 40

6 V ,/ J,

(/J

2' "‘

_

Q

.

,-1 _

G5 20

0.4

~ .ivié

' . ?@,(f\\e if Q ea(\\\ , é- 75 a k ’

0

0 0_2 0.6 0.8 1_0 ( 5 “

Composition (% C) .~ 5 ` .» et...

(H) (D)

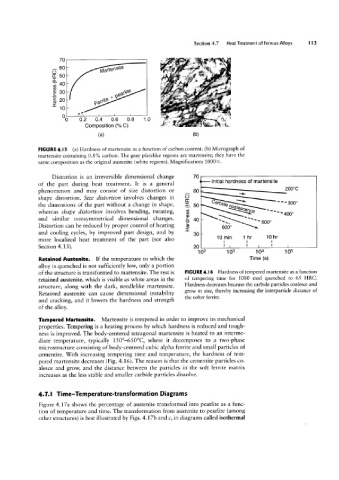

FIGURE 4.I5 (a) Hardness of martensite as a function of carbon content. (b) Micrograph of

martensite containing 0.8% carbon. The gray platelike regions are martensite; they have the

same composition as the original austenite (white regions). Magnification: 1000><.

Distortion is an irreversible dimensional change

of the part during heat treatment. It is a general 70 Initial hardness of martensite

_>

phenomenon and may consist of size distortion or 6 60 %t=e go0°C

shape distortion. Size distortion involves changes in

the dimensions of the part without a change in shape, 3 50 Ca’b’d@ co T* T _ ` ` 300°

whereas shape distortion involves bending, twisting, <5 _ 400 .

Q,

and similar nonsymmetrical dimensional changes. "~. ""5o0°

I

Distortion can be reduced by proper control of heating § 40 600°

and cooling cycles, by improved part design, and by

more localized heat treatment of the part (see also 30 10 min 1 hr 10 hr

Section 4.13). 20

102 103 104 105

Retained Austenite. If the temperature to which the Time (S)

alloy is quenched is not sufficiently low, only a portion

of the structure is transformed to martensite. The rest is FIGURE 4.I6 Hardness of tempered martensite as a function

retained austenite, which is visible as white areas in the of tempering time for 1080 steel quenched to 65 HRC.

structure, along with the dark, needlelike martensite. Hardness decreases because the carbide particles coalesce and

Retained austenite can cause dimensional instability grow in size, thereby increasing the interparticle distance of

and cracking, and it lowers the hardness and strength the softer ferrite.

of the alloy.

Tempered Martensite. Martensite is tempered in order to improve its mechanical

properties. Tempering is a heating process by which hardness is reduced and tough-

ness is improved. The body-centered tetragonal martensite is heated to an interme-

diate temperature, typically 15 0°-650°C, where it decomposes to a two-phase

microstructure consisting of body-centered cubic alpha ferrite and small particles of

cementite. With increasing tempering time and temperature, the hardness of tem-

pered martensite decreases (Fig. 4.16). The reason is that the cementite particles co-

alesce and grow, and the distance between the particles in the soft ferrite matrix

increases as the less stable and smaller carbide particles dissolve.

4.1.I Time-Temperature-transformation Diagrams

Figure 4.17a shows the percentage of austenite transformed into pearlite as a func-

tion of temperature and time. The transformation from austenite to pearlite (among

other structures) is best illustrated by Figs. 4.17b and c, in diagrams called isothermal