Page 41 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 41

Section 1.6 Selection of Manufacturing Processes

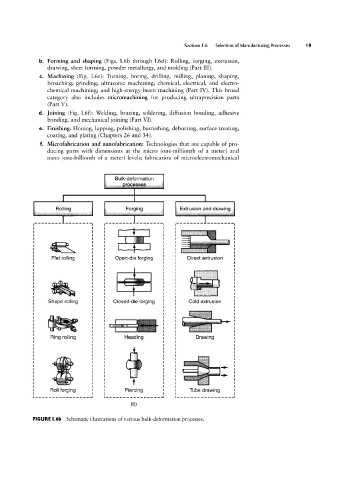

Forming and shaping (Figs. I.6b through I.6d): Rolling, forging, extrusion,

drawing, sheet forming, powder metallurgy, and molding (Part III).

Machining (Fig. I.6e): Turning, boring, drilling, milling, planing, shaping,

broaching; grinding; ultrasonic machining; chemical, electrical, and electro-

chemical machining; and high-energy-beam machining (Part IV). This broad

category also includes micromachining for producing ultraprecision parts

(Part V).

Joining (Fig. l.6f): Welding, brazing, soldering, diffusion bonding, adhesive

bonding, and mechanical joining (Part VI).

Finishing: Honing, lapping, polishing, burnishing, deburring, surface treating,

coating, and plating (Chapters 26 and 34).

Microfabrication and nanofabrication: Technologies that are capable of pro-

ducing parts with dimensions at the micro (one-millionth of a meter) and

nano (one-billionth of a meter) levels; fabrication of microelectromechanical

Bulk-deformation

' , s n .: , »

(_, gl E

L =~

Rolling

L Extrusion and drawing

Forging

~~;,

_V _ _ _ ____ _I I ________ ________ ________ _'_"'' 'I

_* gggg gg

H

_

Flat rolling I I I I Open-die forging : I Direct extrusion : I I I I

Shape rolling Closed-die forging Cold extrusion

-_

...,

Heading

Fling rolling |

Drawing

’i"""' '*

,P : I 1.,,..,...........,.. _> :

' H,.,, *U ' U |

Fioli forging : Piercing Tube drawing

_______-..-_-....| I.-- -_----------_.| I _______________|

(b)

FIGURE l.6b Schematic illustrations of various bulk-deformation processes.