Page 43 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 43

I

Section 1.6 Selection of Manufacturing Processes

Polymer-processing

. * s Qi;

Thermoplastics

, I TIIGIITIOSGIS I Rapid prototyping I,

IIII, ,

I f

-______ -_____ -_-_ _____ I -______ -___----_-

"'

::=.. X I \\;/

__e__,______,_,V,

é

_,,,.,?h

Extrusion Compression molding Stereolithography

.,,,.h,,¢ "1 I A I

Injection molding Pultrusion I Fused-deposition modeling

I

_"im “MM M E E I

_____§__

e e _ 'FF _ W M

IQ

| ‘¥@fE£EE£EE?E??*?&&éééEE€§i£E§£E§?3EiEEEi:E3%E2?€&E&E§SEE

Blow molding Vacuum-bag forming I Three-dimensional printing I

,I 13

www

If sr

IIIIIII

ww

; 7§nn§1 I '

,

'I Laminated-object

Thermoforming Transfer molding I manufacturing

______________ J _______________ J ______________

I I J

ld)

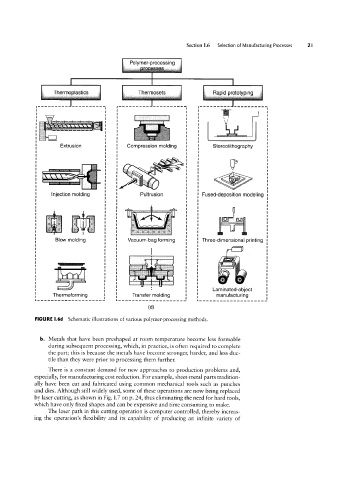

FIGURE I.6d Schematic illustrations of various polymer-processing methods.

b. Metals that have been preshaped at room temperature become less formable

during subsequent processing, vvhich, in practice, is often required to complete

the part; this is because the metals have become stronger, harder, and less duc-

tile than they were prior to processing them further.

There is a constant demand for new approaches to production problems and,

especially, for manufacturing cost reduction. For example, sheet-metal parts tradition-

ally have been cut and fabricated using common mechanical tools such as punches

and dies. Although still Widely used, some of these operations are now being replaced

by laser cutting, as shown in Fig. 1.7 on p. 24, thus eliminating the need for hard tools,

which have only fixed shapes and can be expensive and time consuming to make.

The laser path in this cutting operation is computer controlled, thereby increas-

ing the operation’s flexibility and its capability of producing an infinite variety of