Page 44 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 44

General Introduction

Machining and finishing

'

'i /

lg Machining Advanced machining gg l Finishing 1

;"'""""'""" I :"""`"`<-`f""""i g""""" ""`""

WV'

l @§;€ I \{ 5, I l

:¢@»~~ g l : §%%

é§%%@%

g

|

:M ".;¢¢~;~

éaie

'

: ,f aana i§> : '%%

5 awwif I r g » 1%

'

; ~\ i'ih Qi;

Surface grinding

Turning Wire ESM

E

f

.... _

l

5

l c

Drilling Chemical machining Centerless grinding

I

| 9

' 5

:A l

i

E5 _` ~

E

I' M

ww `

a acccc

§° ...

cr

I Milling Lapping

,c acccca aaaaf _;;;~ aa fi’ ° gg .. ____,,,___ ., __,__

E Laser machining

at

Fffn

K

0 "`““' ""`

¥§1F'

QI (

)

al?"

*-~»‘~an|su

`

+

E Broaching : Water-jet machining iff : Electrochemical polishing

._ ..____________________J .____________________J

(G)

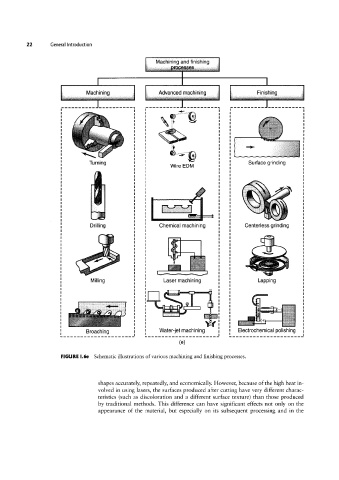

FIGURE l.6e Schematic illustrations of various machining and finishing processes.

shapes accurately, repeatedly, and economically. However, because of the high heat in-

volved in using lasers, the surfaces produced after cutting have very different charac-

teristics (such as discoloration and a different surface texture) than those produced

by traditional methods. This difference can have significant effects not only on the

appearance of the material, but especially on its subsequent processing and in the