Page 45 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 45

Section 1.6 Selection of Manufacturing Processes

it ll

_____;_I _________ , _________

Fastening and bonding

Other welding

Fusion welding

I

I

, .

I

it-If

_222 I

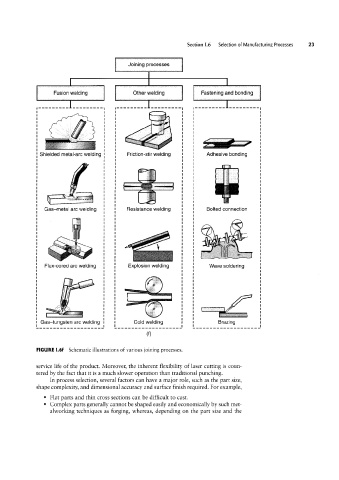

Shielded metal-arc welding I Friction-stir welding Adhesive bonding

I

.- ,. E

I W’

F

I

I 5 I , _

» jf I ' 'f""'ff'fr‘

Ea

~ I I

gg 23 I

I

li M Q

Gas-metal arc welding Resistance welding Bolted connection I

I I

Flux-cored arc welding I Explosion welding Wave soldering I

|

Il

2

I

I Gas-tungsten arc welding I Cold welding Brazing

(I)

FIGURE l.6f Schematic illustrations of various joining processes.

service life of the product. Moreover, the inherent flexibility of laser cutting is coun-

tered by the fact that it is a much slower operation than traditional punching.

In process selection, several factors can have a major role, such as the part size,

shape complexity, and dimensional accuracy and surface finish required. For example,

° Flat parts and thin cross sections can be difficult to cast.

° Complex parts generally cannot be shaped easily and economically by such met-

alworking techniques as forging, whereas, depending on the part size and the