Page 531 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 531

Section 19.13 Processing Polymer matrix Composites

l9.I 3.2 Molding of Reinforced Plastics

There are several molding processes used for reinforced plastics.

Compression Molding. The material is placed between two molds, and pressure is

applied. The molds may be either at room temperature or heated to accelerate hard-

ening of the part. The material may be a bulk-molding compound, which is a vis-

cous, sticky mixture of polymers, fibers, and additives. Generally, it is molded into

the shape of a log, which subsequently is cut or sliced into the desired shape. Fiber

lengths generally range from 3 to 50 mm, although longer fibers of 75 mm also may

be used.

Sheet-molding compounds also can be processed by compression molding.

These compounds are similar to bulk-molding compounds, except that the

resin-fiber mixture is laid between plastic sheets to make a sandwich that can be

handled easily. The sheets have to be removed prior to placing the SMC in the mold.

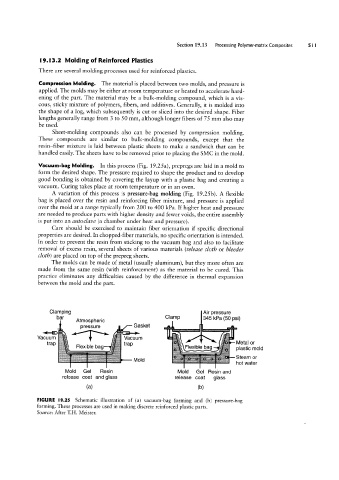

Vacuum-bag Molding. In this process (Fig. 19.25a), prepregs are laid in a mold to

form the desired shape. The pressure required to shape the product and to develop

good bonding is obtained by covering the layup with a plastic bag and creating a

vacuum. Curing takes place at room temperature or in an oven.

Vacuum

A variation of this process is pressure-bag molding (Fig. 19.25 b). A flexible

bag is placed over the resin and reinforcing fiber mixture, and pressure is applied

over the mold at a range typically from ZOO to 400 kPa. If higher heat and pressure

are needed to produce parts with higher density and fewer voids, the entire assembly

is put into an autoclaz/e (a chamber under heat and pressure).

Care should be exercised to maintain fiber orientation if specific directional

properties are desired. ln chopped-fiber materials, no specific orientation is intended.

In order to prevent the resin from sticking to the vacuum bag and also to facilitate

removal of excess resin, several sheets of various materials (release cloth or bleeder

cloth) are placed on top of the prepreg sheets.

The molds can be made of metal (usually aluminum), but they more often are

made from the same resin (with reinforcement) as the material to be cured. This

practice eliminates any difficulties caused by the difference in thermal expansion

between the mold and the part.

Clamping Air pressure

bar Atmospheric Clamp 345 kPa (50 psi)

pressure GaSk€‘t 1, zrtr; ,-

__

,_ Vacuum

_,_:?_z

H

M t

"ap ,\ Flexible bag "ap Flexible bag p|aSti¢ mom

W

e a or

Steam or

Mold Gel Flesin Mold Gel Resin and

release coat and glass release coat glass

(H) (D)

FIGURE l9.25 Schematic illustration of (a) vacuum-bag forming and (b) pressure-bag

forming. These processes are used in making discrete reinforced plastic parts.

Source: After T.H. Meister.