Page 530 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 530

0 Chapter 19 Plastics and Composite Materials: Forming and Shaping

Ama E

(H) (D)

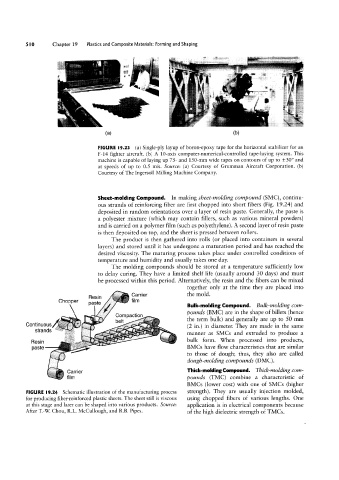

FIGURE I9.23 (a) Single-ply layup of boron-epoxy tape for the horizontal stabilizer for an

F-14 fighter aircraft. (b) A 10-axis computer-numerical-controlled tape-laying system. This

machine is capable of laying up 75- and 150-mm wide tapes on contours of up to i30° and

E 1,

at speeds of up to 0.5 m/s. Source: (a) Courtesy of Grumman Aircraft Corporation. (b)

Courtesy of The Ingersoll Milling Machine Company.

Sheet-molding Compound. In making sheet-molding compound (SMC), continu-

ous strands of reinforcing fiber are first chopped into short fibers (Fig. 1924) and

deposited in random orientations over a layer of resin paste. Generally, the paste is

a polyester mixture (which may contain fillers, such as various mineral powders)

and is carried on a polymer film (such as polyethylene). A second layer of resin paste

is then deposited on top, and the sheet is pressed between rollers.

The product is then gathered into rolls (or placed into containers in several

layers) and stored until it has undergone a maturation period and has reached the

desired viscosity. The maturing process takes place under controlled conditions of

paste paste be processed within this period. Alternatively, the resin and the fibers can be mixed

temperature and humidity and usually takes one day.

The molding compounds should be stored at a temperature sufficiently low

to delay curing. They have a limited shelf life (usually around 30 days) and must

together only at the time they are placed into

the mold.

M Hégg

Resin Carrier

ContinuouS/ Compaction gay vp plpunds art;in the sgape of billets5%1ence

Chopper film

_

Resin as

Bulk-moldzng com-

Bulk-molding Compound.

a*

t e term

an genera y are up to

mm

gi;

u

Strands -

Vp p_;i1,.), .,V_

(2 in.) in diameter. They are made in the same

bulk form. When processed into products,

BMCS have flow characteristics that are similar

Q manner as SMCs and extruded to produce a

dough-molding compounds (DMC).

to those of dough; thus, they also are called

Carrier Thick-moldingCompound. Thick-molding corn-

film pounds (TMC) combine a characteristic of

BMCS (lower cost) with one of SMCs (higher

FIGURE I9.24 Schematic illustration of the manufacturing process strength). They are usually injection molded,

for producing fiber-reinforced plastic sheets. The sheet still is viscous using chopped fibers of various lengths. One

at this stage and later can be shaped into various products. Source: application is in electrical components because

After T.-W. Chou, R.L. McCullough, and R.B. Pipes. of the high dielectric strength of TMCS.