Page 525 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 525

Section 19 9 Castlng 0

compression molding, and some excess material is left in the channels of the mold

during filling, which is later removed.

I9.9 Casting

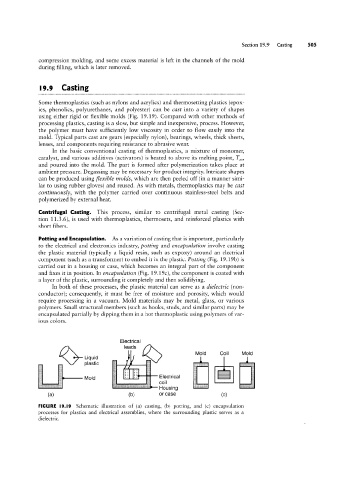

Some thermoplastics (such as nylons and acrylics) and thermosetting plastics (epox-

ies, phenolics, polyurethanes, and polyester) can be cast into a variety of shapes

using either rigid or flexible molds (Fig. 1919). Compared with other methods of

processing plastics, casting is a slovv, but simple and inexpensive, process. However,

the polymer must have sufficiently low viscosity in order to flow easily into the

mold. Typical parts cast are gears (especially nylon), bearings, wheels, thick sheets,

lenses, and components requiring resistance to abrasive vvear.

In the basic conventional casting of thermoplastics, a mixture of monomer,

catalyst, and various additives (activators) is heated to above its melting point, Tm,

and poured into the mold. The part is formed after polymerization takes place at

ambient pressure. Degassing may be necessary for product integrity. lntricate shapes

can be produced using flexible inolcls, Which are then peeled off (in a manner simi-

lar to using rubber gloves) and reused. As with metals, thermoplastics may be cast

continuously, With the polymer carried over continuous stainless-steel belts and

polymerized by external heat.

Centrifugal Casting. This process, similar to centrifugal metal casting (Sec-

tion 1l.3.6), is used with thermoplastics, thermosets, and reinforced plastics with

short fibers.

Potting and Encapsulation. As a variation of casting that is important, particularly

to the electrical and electronics industry, potting and encapsulation involve casting

the plastic material (typically a liquid resin, such as expoxy) around an electrical

component (such as a transformer) to embed it in the plastic. Potting (Fig. 19.19b) is

carried out in a housing or case, which becomes an integral part of the component

and fixes it in position. In encapsulation (Fig. 19.19c), the component is coated with

a layer of the plastic, surrounding it completely and then solidifying.

In both of these processes, the plastic material can serve as a dielectric (non-

conductor); consequently, it must be free of moisture and porosity, which would

require processing in a vacuum. Mold materials may be metal, glass, or various

polymers. Small structural members (such as hooks, studs, and similar parts) may be

encapsulated partially by dipping them in a hot thermoplastic using polymers of var-

ious colors.

L|qu|d ’ _ Z35iE§€ iE€E’EE§i%%E Coil -mis |\/Io d

Electrical

leads

|\/Iold

p asm C

..._ ,.,,. -

HOu Si n Q

' '=='===¥¥ =? = ~=ee =¥¢f'=s==‘ === <=¢¢======

(3) ._. ._.,. ,, ,......._.,.. CO" (C)

Ol' CHSG

FIGURE l9.l9 Schematic illustration of (a) casting, (b) potting, and (c) encapsulation

processes for plastics and electrical assemblies, Where the surrounding plastic serves as a

dielectric.