Page 520 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 520

V H JAAA Kmfe

Extruder

Extruded =, .. Heating Tail

parison V

mold 1 . my I

0 0

Blown bottle

Mold closed

Blow pin and bottle blown

(3)

i* Blow pin

removed

-=.

l,~,

'~1@<=t<>~-m<>'di~Q

Blow pin

wl»l

machine

Passages ,:_= Bmwn

bottle

Coolmg _,<,J

Parison mold Parison transferred

to blow mold

(D)

® Blown-mold station

\

B' W_mO|d Core-pin opening 3

0 ¢ \ (Blown air passage) /

Jw

bottom plug ",V \ Blow mold f,/

Blown bottle parison /fl

\ V' _

Blow-mold direction ®Preform

mold station

~

neck rinQ Xing M V, T___r_>

"" "

* *' , \ _ § gY@jiE|E|Ei!_ i

""E'g'§'g'c"&'tc'

“"

'

Transfer \ . .g '

2

“=ai¥2€ff`“

H g !-\5'5"='d~.-E

head _ _l Reciprocating-screw extruder

@ Stripper station ,gr

Stripper plate Ng”

Bome '”'\ Preform Preform

J? neck ring mold

(C)

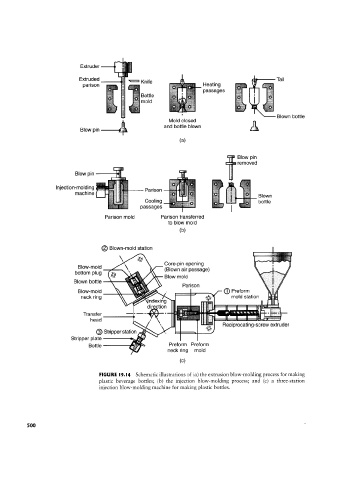

FIGURE |9.l4 Schematic illustrations of (a) the extrusion blow-molding process for making

plastic beverage bottles; (b) the injection blow-molding process; and (c) a three-station

injection blow-molding machine for making plastic bottles.