Page 521 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 521

Section 19.5 Rotational Molding 50|

dies then open, and the parison is transferred to a blow-molding die by an indexing

mechanism (Fig. 19.14c). Hot air is injected into the parison, expanding it to the

walls of the mold cavity. Typical products made are plastic beverage bottles (typically

made of polyethylene or polyetheretherketone, PEEK) and small, hollow containers.

A related process is stretch blow molding, in which the parison is expanded and elon-

gated simultaneously, subjecting the polymer to biaxial stretching and thus enhancing

its properties.

Multilayer blow molding involves the use of coextruded tubes or parisons and

thus permits the production of a multilayer structure (see Fig. 19.4b). A typical ex~

ample of such a product is plastic packaging for food and beverages, having such

characteristics as odor and permeation barrier, taste and aroma protection, scuff

resistance, the capability of being printed, and the ability to be filled with hot fluids.

Other applications of this process are for containers in the cosmetics and the phar-

maceutical industries.

l9.5 Rotational Molding

Pressurizing

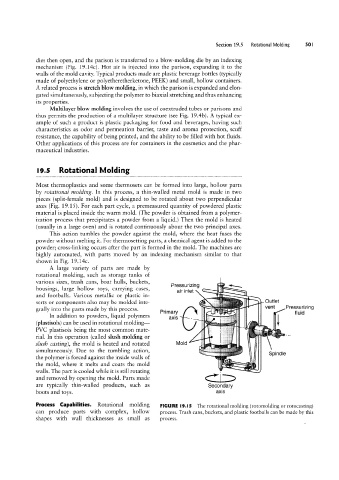

Most thermoplastics and some thermosets can be formed into large, hollow parts

by rotational molding. In this process, a thin-walled metal mold is made in two

pieces (split-female mold) and is designed to be rotated about two perpendicular

axes (Fig. 19.15 ). For each part cycle, a premeasured quantity of powdered plastic

material is placed inside the warm mold. (The powder is obtained from a polymer-

ization process that precipitates a powder from a liquid.) Then the mold is heated

(usually in a large oven) and is rotated continuously about the two principal axes.

This action tumbles the powder against the mold, where the heat fuses the

powder without melting it. For thermosetting parts, a chemical agent is added to the

powder; cross-linking occurs after the part is formed in the mold. The machines are

highly automated, with parts moved by an indexing mechanism similar to that

shown in Fig. 19.14c.

A large variety of parts are made by

rotational molding, such as storage tanks of S?" g

various sizes, trash cans, boat hulls, buckets,

housings, large hollow toys, carrying cases,

air inlet ,

and footballs. Various metallic or plastic in-

serts or components also may be molded inte- % L U 5 o 1| r

grally into the parts made by this process. veunte Pressurizing

In addition to powders, liquid polymers Pf"“aFY flwd

(plastisols) can be used in rotational molding- fll l ll

PVC plastisols being the most common mate- aél ll I,

rial. In this operation (called slush molding or

slush casting), the mold is heated and rotated Mold u ~

simultaneously. Due to the tumbling action, Ml Spindle

the polymer is forced against the inside walls of

5,!-...,.,,____

the mold, where it melts and coats the mold GLQ

walls. The part is cooled while it is still rotating

and removed by opening the mold. Parts made QLD

are typically thin-walled products, such as Secondary

boots and toys. axis

Process Capabilities. Rotational molding FIGURE l9.I5 The rotational molding (rotomolding or rotocasting)

can produce parts with complex, hollow process. Trash cans, buckets, and plastic footballs can be made by this

shapes with wall thicknesses as small as process.