Page 516 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 516

6 Chapter 19 Plastics and Composite Materials: Forming and Shaping

Stripper

S

Plate Gate Plate Plate Plate Plate

(pat

Sprue Sprue

bushing

._+ prue Ejector bushing Ejector

Pins 3 pins

'r’= Paris

Runner

(3) (U)

Hot plate;

Runner stays molten Plate

bushing

Plate

Ei<=>°f°f

_+ T pins

Parts

(C)

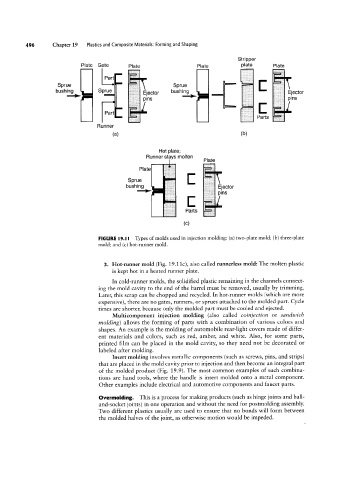

FIGURE l9.| I Types of molds used in injection molding: (a) two-plate mold; (b) three-plate

mold; and (c) hot-runner mold.

3. Hot-runner mold (Fig. 19.11c), also called runnerless mold: The molten plastic

is kept hot in a heated runner plate.

In cold-runner molds, the solidified plastic remaining in the channels connect-

ing the mold cavity to the end of the barrel must be removed, usually by trimming.

Later, this scrap can be chopped and recycled. In hot-runner molds (which are more

expensive), there are no gates, runners, or sprues attached to the molded part. Cycle

times are shorter, because only the molded part must be cooled and ejected.

Multicomponent injection molding (also called coinjection or sandwich

molding) allows the forming of parts with a combination of various colors and

shapes. An example is the molding of automobile rear-light covers made of differ-

ent materials and colors, such as red, amber, and white. Also, for some parts,

printed film can be placed in the mold cavity, so they need not be decorated or

labeled after molding.

Insert molding involves metallic components (such as screws, pins, and strips)

that are placed in the mold cavity prior to injection and then become an integral part

of the molded product (Fig. 19.9). The most common examples of such combina-

tions are hand tools, Where the handle is insert molded onto a metal component.

Other examples include electrical and automotive components and faucet parts.

Overmolding. This is a process for making products (such as hinge joints and ball-

and-socket joints) in one operation and without the need for postmolding assembly.

Two different plastics usually are used to ensure that no bonds will form between

the molded halves of the joint, as otherwise motion would be impeded.