Page 511 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 511

Section 19.2 Extrusion 49|

\@@l

Pinch rolls

WinC|'UD 0 .U 0 Guide rolls

O Q

I 0

Blown

tube

Mandrel `

Extruder

§"§

Die I

II'

iAir

(H) (0)

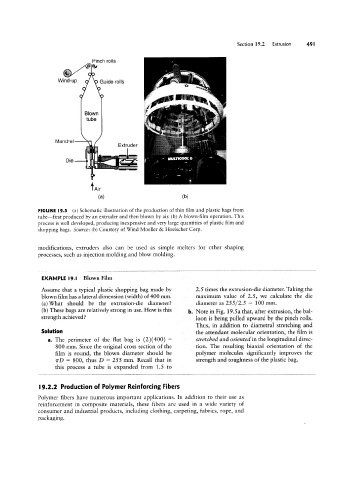

FIGURE l9.5 (a) Schematic illustration of the production of thin film and plastic bags from

tube-first produced by an extruder and then blown by air. (b) A blown-film operation. This

process is well developed, producing inexpensive and very large quantities of plastic film and

shopping bags. Source: (b) Courtesy of Wind Moeller 86 Hoelscher Corp.

modifications, extruders also can be used as simple melters for other shaping

processes, such as injection molding and blow molding.

EXAMPLE |9.l Blown Film

Assume that a typical plastic shopping bag made by 2.5 times the extrusion-die diameter. Taking the

blown film has a lateral dimension (width) of 400 mm. maximum value of 2.5, we calculate the die

(a) What should be the extrusion-die diameter? diameter as 255/2.5 = 100 mm.

(b) These bags are relatively strong in use. How is this Note in Fig. 19.5a that, after extrusion, the bal-

strength achieved? loon is being pulled upward by the pinch rolls.

Thus, in addition to diametral stretching and

Solution the attendant molecular orientation, the film is

a. The perimeter of the flat bag is (2)(400) = stretched and oriented in the longitudinal direc-

800 mm. Since the original cross section of the tion. The resulting biaxial orientation of the

film is round, the blown diameter should be polymer molecules significantly improves the

11D = 800, thus D = 255 mm. Recall that in strength and toughness of the plastic bag.

this process a tube is expanded from 1.5 to

l9.2.2 Production of Polymer Reinforcing Fibers

Polymer fibers have numerous important applications. In addition to their use as

reinforcement in composite materials, these fibers are used in a wide variety of

consumer and industrial products, including clothing, carpeting, fabrics, rope, and

packaging.