Page 512 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 512

492 Chapter 19 Plastics and Composite Materials: Forming and Shaping

V.; powmer Most synthetic fibers used in reinforced plastics are

ol mers that are extruded throu h the tin holes of a device

~ ,M Chi 5 "t cal bl ifower ea Zi ) to form contin-

_~

ies, spinneret uous filaments of semisolid polymer. The extruder forces the

p

P iyed a spinneret (resem ing a s

11

`~ Feed

M

polymer through the spinneret, which may have from one

\ hopper

to several hundred holes. If the polymers are thermoplas-

i

§

SP'V"'"V‘Q M

tics, they first are melted in the extruder, as described in

&’Hh?;'*~»~”*

,`,,_`*m_m,;g

Melter/extruder _ “iii y»y" ~ section 19 2 Th_ _ ermosetting po 1 ymers a so can be forme d

1

|\/lelt

\‘

into fibers by first dissolving or chemically treating them so

Cold air

that they can be extruded. These operations are performed at

high production rates and with very high reliability.

As the filaments emerge from the holes in the spinneret,

fy,” W//f/Q the liquid polymer is first converted to a rubbery state and

V//wwf,

Bobbin then solidified. This process of extrusion and solidification of

_

i

~i

continuous filaments is called spinning. The term spinning

also is used for the production of natural textiles (such as

~¢i-~~~» t h_ I cotton or wool), where short pieces of fiber are twisted into

St yarn. There are four methods of spinning fibers: melt, wet,

re C mg dry, and gel spinning.

5 Twisting and

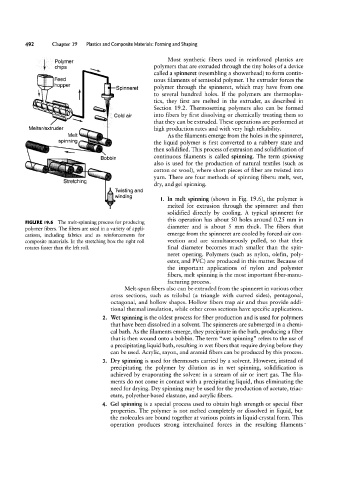

Winding I. In melt spinning (shown in Fig. 19.6), the polymer is

melted for extrusion through the spinneret and then

:V

solidified directly by cooling. A typical spinneret for

this operation has about 50 holes around 0.25 mm in

FIGURE l9.6 The melt-spinning process for producing

diameter and is about 5 mm thick. The fibers that

polymer fibers. The fibers are used in a variety of appli-

cations, including fabrics and as reinforcements for emerge from the spinneret are cooled by forced-air con-

composite materials. In the stretching box the right roll vection and are simultaneously pulled, so that their

rotates faster than the left roll. final diameter becomes much smaller than the spin-

neret opening. Polymers (such as nylon, olefin, poly-

ester, and PVC) are produced in this matter. Because of

the important applications of nylon and polyester

fibers, melt spinning is the most important fiber-manu-

facturing process.

Melt-spun fibers also can be extruded from the spinneret in various other

cross sections, such as trilobal (a triangle with curved sides), pentagonal,

octagonai, and hollow shapes. Hollow fibers trap air and thus provide addi-

tional thermal insulation, while other cross sections have specific applications.

2. Wet spinning is the oldest process for fiber production and is used for polymers

that have been dissolved in a solvent. The spinnerets are submerged in a chemi-

cal bath. As the filaments emerge, they precipitate in the bath, producing a fiber

that is then wound onto a bobbin. The term “wet spinning” refers to the use of

a precipitating liquid bath, resulting in wet fibers that require drying before they

can be used. Acrylic, rayon, and aramid fibers can be produced by this process.

3. Dry spinning is used for thermosets carried by a solvent. However, instead of

precipitating the polymer by dilution as in wet spinning, solidification is

achieved by evaporating the solvent in a stream of air or inert gas. The fila-

ments do not come in contact with a precipitating liquid, thus eliminating the

need for drying. Dry spinning may be used for the production of acetate, triac-

etate, polyether-based elastane, and acrylic fibers.

4. Gel spinning is a special process used to obtain high strength or special fiber

properties. The polymer is not melted completely or dissolved in liquid, but

the molecules are bound together at various points in liquid-crystal form. This

operation produces strong interchained forces in the resulting filaments