Page 509 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 509

Section 19.2 Extrusion 489

Extruders generally are rated by the diameter, D, of the barrel and the length-

to~diameter (L/D) ratio of the barrel. Machinery costs can be on the order of

$300,000, including the cost for the equipment for downstream cooling and wind-

ing of the extruded product.

I9.2.l Miscellaneous Extrusion Processes

There are several variations of the basic extrusion process for producing a number

of different products.

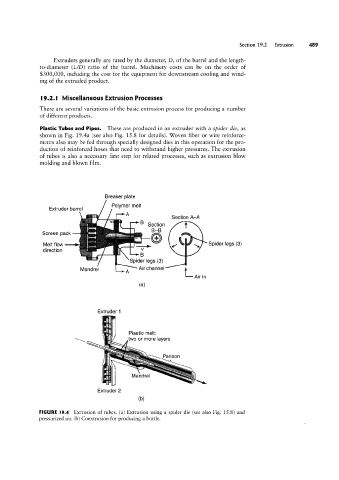

Plastic Tubes and Pipes. These are produced in an extruder with a spider die, as

shown in Fig. 19.421 (see also Fig. 15.8 for details). Woven fiber or wire reinforce-

ments also may be fed through specially designed dies in this operation for the pro-

duction of reinforced hoses that need to withstand higher pressures. The extrusion

of tubes is also a necessary first step for related processes, such as extrusion blow

molding and blown film.

X

Breaker plate

Polymer melt

Extruder barrel

Section A-A

B Section f

%

Screen pack

_,

Melt flow 5/ Q »:'f Spider |995 (3)

direction V

B

legs (3)

|\/|and,»e| Air channel Air in

(8)

Extruder 1

.EE "

.zjgi

Plastic melt:

‘§f§i

two or more layers

Parison

V Mandrel '~» ~ \;

Extruder 2

(D)

FIGURE l9.4 Extrusion of tubes. (a) Extrusion using a spider die (see also Fig. 15.8) and

pressurized air. (b) Coextrusion for producing a bottle.