Page 508 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 508

88 Chapter 19 Plastics and Composite Materials: Forming and Shaping

Melt inlet

End late

p Die b0ClY Melt-distribution

Melt distribution bo" manifold

manifold Die , -|-hermocou ple well

Preland

Die land Fixed lip

End Seal Adjustable lip

(2)

0 Eii lj

Die Extruded

Shape product Die shape Extruded Die shape Extruded

product product

(bl (C)

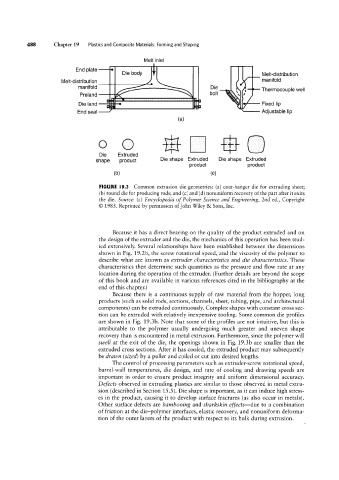

FIGURE l9.3 Common extrusion die geometries: (a) coat-hanger die for extruding sheet;

(b) round die for producing rods; and (c) and (d) nonuniform recovery of the part after it exits

the die. Source: (a) Encyclopedia of Polymer Science and Engineering, 2nd ed., Copyright

© 1985. Reprinted by permission of John Wiley Sc Sons, Inc.

Because it has a direct bearing on the quality of the product extruded and on

the design of the extruder and the die, the mechanics of this operation has been stud-

ied extensively. Several relationships have been established between the dimensions

shown in Fig. 19.2b, the screw rotational speed, and the viscosity of the polymer to

describe what are known as extruder characteristics and die characteristics. These

characteristics then determine such quantities as the pressure and flow rate at any

location during the operation of the extruder. (Further details are beyond the scope

of this book and are available in various references cited in the bibliography at the

end of this chapter.)

Because there is a continuous supply of raw material from the hopper, long

products (such as solid rods, sections, channels, sheet, tubing, pipe, and architectural

components) can be extruded continuously. Complex shapes with constant cross sec-

tion can be extruded with relatively inexpensive tooling. Some common die profiles

are shown in Fig. 19.3b. Note that some of the profiles are not intuitive, but this is

attributable to the polymer usually undergoing much greater and uneven shape

recovery than is encountered in metal extrusion. Furthermore, since the polymer will

swell at the exit of the die, the openings shown in Fig.19.3b are smaller than the

extruded cross sections. After it has cooled, the extruded product may subsequently

be drawn (sized) by a puller and coiled or cut into desired lengths.

The control of processing parameters such as extruder-screw rotational speed,

barrel-wall temperatures, die design, and rate of cooling and drawing speeds are

important in order to ensure product integrity and uniform dimensional accuracy.

Defects observed in extruding plastics are similar to those observed in metal extru-

sion (described in Section 15 .5 ). Die shape is important, as it can induce high stress-

es in the product, causing it to develop surface fractures (as also occur in metals).

Other surface defects are bambooing and slvarleskin effects-due to a combination

of friction at the die-polymer interfaces, elastic recovery, and nonuniform deforma-

tion of the outer layers of the product with respect to its bull< during extrusion.