Page 519 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 519

exchanger Section 19 4 Blow Molding

Heat

Displacement

Pump

Heat

exchanger cy||nders\. ‘ ff” W S tirrer

l\/lOl`lOlT1€l'2

-

fa

*fe Recirculation

Stirrer loop

Monomer 1 Mixing

Reoi rculation i “Gad

loop

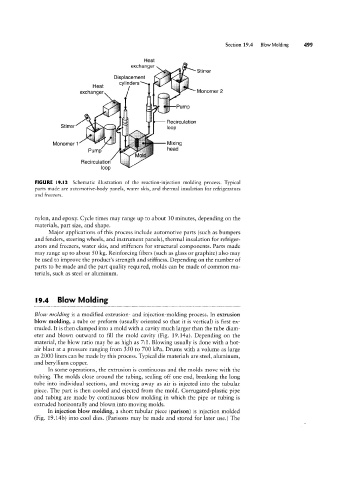

FIGURE l9.l3 Schematic illustration of the reaction-injection molding process. Typical

parts made are automotive-body panels, water skis, and thermal insulation for refrigerators

and freezers.

nylon, and epoxy. Cycle times may range up to about 10 minutes, depending on the

materials, part size, and shape.

Major applications of this process include automotive parts (such as bumpers

and fenders, steering wheels, and instrument panels), thermal insulation for refriger-

ators and freezers, water skis, and stiffeners for structural components. Parts made

may range up to about 50 kg. Reinforcing fibers (such as glass or graphite) also may

be used to improve the product’s strength and stiffness. Depending on the number of

parts to be made and the part quality required, molds can be made of common ma-

terials, such as steel or aluminum.

|9.4 Blow Molding

Blow molding is a modified extrusion- and injection-molding process. In extrusion

blow molding, a tube or preform (usually oriented so that it is vertical) is first ex-

truded. lt is then clamped into a mold with a cavity much larger than the tube diam-

eter and blown outward to fill the mold cavity (Fig. l9.14a). Depending on the

material, the blow ratio may be as high as 7:1. Blowing usually is done with a hot-

air blast at a pressure ranging from 350 to 700 kPa. Drums with a volume as large

as 2000 liters can be made by this process. Typical die materials are steel, aluminum,

and beryllium copper.

In some operations, the extrusion is continuous and the molds move with the

tubing. The molds close around the tubing, sealing off one end, breaking the long

tube into individual sections, and moving away as air is injected into the tubular

piece. The part is then cooled and ejected from the mold. Corrugated-plastic pipe

and tubing are made by continuous blow molding in which the pipe or tubing is

extruded horizontally and blown into moving molds.

In injection blow molding, a short tubular piece (parison) is injection molded

(Fig. 19.14b) into cool dies. (Parisons may be made and stored for later use.) The