Page 523 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 523

Section 19.7 Compression Molding 503

molds have small through-holes in order to aid vacuum forming. These holes typi-

cally are less than 0.5 mm in diameter; otherwise, they would leave marks on the

parts formed. Defects encountered in thermoforming include (a) tearing of the sheet

during forming, (bl nonuniform wall thickness, (c) improperly filled molds, (d) poor

part definition, and (e) lack of surface details.

l9.7 Compression Molding

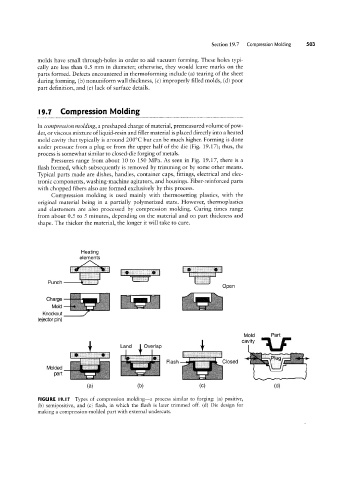

In compression molding, a preshaped charge of material, premeasured volume of pow-

der, or viscous mixture of liquid-resin and filler material is placed directly into a heated

mold cavity that typically is around 200°C but can be much higher. Forming is done

under pressure from a plug or from the upper half of the die (Fig. 19.17); thus, the

process is somewhat similar to closed-die forging of metals.

Pressures range from about 10 to 150 MPa. As seen in Fig. 19.17, there is a

flash formed, which subsequently is removed by trimming or by some other means.

Typical parts made are dishes, handles, container caps, fittings, electrical and elec-

tronic components, washing-machine agitators, and housings. Fiber-reinforced parts

with chopped fibers also are formed exclusively by this process.

Compression molding is used mainly with thermosetting plastics, with the

original material being in a partially polymerized state. However, thermoplastics

and elastomers are also processed by compression molding. Curing times range

from about 0.5 to 5 minutes, depending on the material and on part thickness and

shape. The thicker the material, the longer it will take to cure.

Heating

Q

elements ,,_,

Punch a»~aa ~fs,f»fff,»=.~1~ ~~=f»»»

Open

Land Overlap cavity Part

Knockout

(ejector pin)

Mold

Q

...., ,...._..,,,..,.....

"~» 1 Flash Closed

:;;f

part it MW ,,

(H) (D) (C) (Ol)

FIGURE l9.|7 Types of compression molding-a process similar to forging: (a) positive,

(b) semipositive, and (c) flash, in which the flash is later trimmed off. (d) Die design for

making a compression-molded part with external undercuts.