Page 524 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 524

50 Chapter 19 Plastics and Composite Materials: Forming and Shaping

Process Capabilities. Three types of compression molds are available:

° Flash type: for shallow or flat parts

° Positive type: for high-density parts

° Semipositive type: for quality production.

Undercuts in parts are not recommended; however, dies can be designed to

open sideways (Fig. 19.17d) to allow removal of the molded part. In general, the

complexity of parts produced is less than that from injection molding, but the dimen-

sional control is better. Surface areas of compression-molded parts may range up to

about 2.5 ml. Because of their relative simplicity, dies for compression molding gen-

erally are less costly than those used in injection molding. They typically are made of

tool steels and may be chrome plated or polished for an improved surface finish of

the molded product.

l9.8 Transfer Molding

_£4

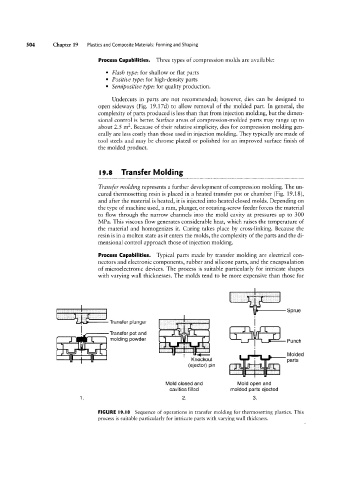

Transfer molding represents a further development of compression molding. The un-

cured thermosetting resin is placed in a heated transfer pot or chamber (Fig. 1918),

and after the material is heated, it is injected into heated closed molds. Depending on

the type of machine used, a ram, plunger, or rotating-screw feeder forces the material

;f 'lie

to flow through the narrow channels into the mold cavity at pressures up to 300

MPa. This viscous flow generates considerable heat, which raises the temperature of

the material and homogenizes it. Curing takes place by cross-linking. Because the

Knockout

resin is in a molten state as it enters the molds, the complexity of the parts and the di-

mensional control approach those of injection molding.

Process Capabilities. Typical parts made by transfer molding are electrical con-

nectors and electronic components, rubber and silicone parts, and the encapsulation

of microelectronic devices. The process is suitable particularly for intricate shapes

with varying wall thicknesses. The molds tend to be more expensive than those for

Spfue

Transfer plunger ttr* *

Transfer pot and *“

|1lll|{| ...ara punch

__|__ _-__ molding powder

l.Ll-JI1-J_l.l lw i” Mme.,

1l_3l1

Z i1f

‘

(ejector) pin parts

l\/lold closed and Mold open and

cavities filled molded parts ejected

2. 3.

FIGURE l9.I8 Sequence of operations in transfer molding for thermosetting plastics. This

process is suitable particularly for intricate parts with varying wall thickness.