Page 529 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 529

Section 19.13 Processing Polymer matrix Composites

duction rate, An important safety and environmental concern in reinforced plastics

is the dust generated during processing. For example, airborne carbon fibers are

known to remain in the Work area long after the fabrication of parts has been com-

pleted.

l9.l 3.l Fiber lmpregnation

In order to obtain good bonding between the reinforcing fibers and the polymer ma-

trix and to protect them during handling, fibers are surface treated by impregnation

(sizing). When impregnation is carried out as a separate step, the resulting partially

cured sheets are called by various terms.

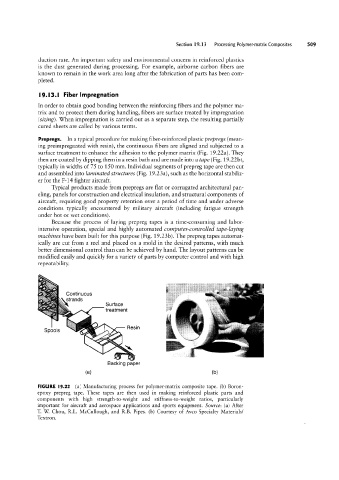

Prepregs. In a typical procedure for making fiber-reinforced plastic prepregs (mean-

ing preimpregnated with resin), the continuous fibers are aligned and subjected to a

surface treatment to enhance the adhesion to the polymer matrix (Fig. 19.22a). They

then are coated by dipping them in a resin bath and are made into a tape (Fig. 19.22b),

typically in widths of 75 to 150 mm. Individual segments of prepreg tape are then cut

and assembled into laminated structures (Fig. 19.23a), such as the horizontal stabiliz-

er for the F-14 fighter aircraft.

Typical products made from prepregs are flat or corrugated architectural pan-

eling, panels for construction and electrical insulation, and structural components of

aircraft, requiring good property retention over a period of time and under adverse

conditions typically encountered by military aircraft (including fatigue strength

under hot or Wet conditions).

Because the process of laying prepreg tapes is a time-consuming and labor-

intensive operation, special and highly automated computer-controlled tape-laying

machines have been built for this purpose (Fig. 19.Z3b). The prepreg tapes automat-

ically are cut from a reel and placed on a mold in the desired patterns, with much

Continuous S rf

better dimensional control than can be achieved by hand. The layout patterns can be

modified easily and quickly for a variety of parts by computer control and with high

repeatability.

35"

trands

u ace

Spools treatment

at A.; /» Resm

Backing paper

(fi) (b)

FIGURE l9.22 (a) Manufacturing process for polymer-matrix composite tape. (b) Boron-

epoxy prepreg tape. These tapes are then used in making reinforced plastic parts and

components with high strength-to-vveiht and stiffness-to-Weight ratios, particularly

important for aircraft and aerospace applications and sports equipment. Source: (a) After

T. W Chou, R.L. McCullough, and R.B. Pipes. (b) Courtesy of Avco Specialty Materials/

Textron.