Page 532 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 532

2 Chapter 19 Plastics and Composite Materials: Forming and Shaping

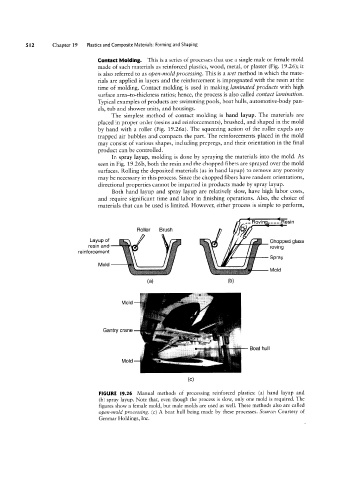

Contact Molding. This is a series of processes that use a single male or female mold

made of such materials as reinforced plastics, wood, metal, or plaster (Fig. 19.26 ); it

is also referred to as open-mold processing. This is a wet method in which the mate-

rials are applied in layers and the reinforcement is impregnated with the resin at the

time of molding. Contact molding is used in making laminated products with high

surface area-to-thickness ratios; hence, the process is also called contact lamination.

Typical examples of products are swimming pools, boat hulls, automotive-body pan-

els, tub and shower units, and housings.

The simplest method of contact molding is hand layup. The materials are

placed in proper order (resins and reinforcements), brushed, and shaped in the mold

by hand with a roller (Fig. l9.26a). The squeezing action of the roller expels any

trapped air bubbles and compacts the part. The reinforcements placed in the mold

may consist of various shapes, including prepregs, and their orientation in the final

product can be controlled.

In spray layup, molding is done by spraying the materials into the mold. As

seen in Fig. 19.26b, both the resin and the chopped fibers are sprayed over the mold

surfaces. Rolling the deposited materials (as in hand layup) to remove any porosity

\‘ O

may be necessary in this process. Since the chopped fibers have random orientations,

directional properties cannot be imparted in products made by spray layup.

Both hand layup and spray layup are relatively slow, have high labor costs,

and require significant time and labor in finishing operations. Also, the choice of

materials that can be used is limited. However, either process is simple to perform,

_,__ Rovin ____ .Resin

0%

Roller Brush . /

resin and \ f Ch d

.,.,i,

Layup of

reinforcement ifilvt ,M Q) rovi)|'l>giDe Q ass

Spray

More -

.rri,r i"ii1 l'ir".~ 5333 =‘~ir.“ if MOM

(3) (D)

Mold-

Gantry crane-

- Boat hull

Mold-

T (C)

FIGURE |9.26 Manual methods of processing reinforced plastics: (a) hand layup and

(b) spray layup. Note that, even though the process is slow, only one mold is required. The

figures show a female mold, but male molds are used as well. These methods also are called

open-mold processing. (c) A boat hull being made by these processes. Source: Courtesy of

Genmar Holdings, Inc.