Page 534 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 534

PU|ffUSi<>f\

out to length

]"*‘“<|

Plastics and Composite Materials: Forming and Shaping

5 I4 Chapter 19 Saw

*~1»

belt _tt

Preforming die

e9?Qé¢

Txvi.

Heated die Q.,

Moving ’

<30

Prepreg

feed system

Infiltration tank

Cured

Puller pultrusion

(fi) (D)

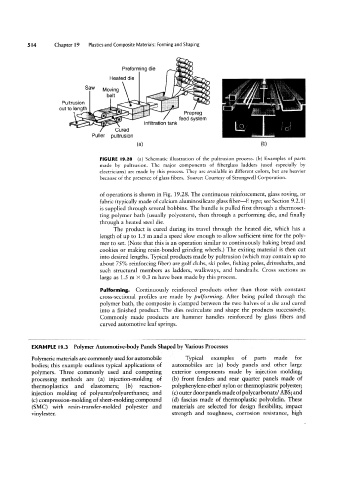

FIGURE |9.28 (a) Schematic illustration of the pultrusion process. (b) Examples of parts

made by pultrusion. The major components of fiberglass ladders (used especially by

electricians) are made by this process. They are available in different colors, but are heavier

because of the presence of glass fibers. Source: Courtesy of Strongwell Corporation.

of operations is shown in Fig. 19.28. The continuous reinforcement, glass roving, or

fabric (typically made of calcium aluminosilicate glass fiber-E type; see Section 9.2.1)

is supplied through several bobbins. The bundle is pulled first through a thermoset-

ting polymer bath (usually polyesters), then through a performing die, and finally

through a heated steel die.

The product is cured during its travel through the heated die, which has a

length of up to 1.5 m and a speed slow enough to allow sufficient time for the poly-

mer to set. (Note that this is an operation similar to continuously baking bread and

cookies or making resin-bonded grinding wheels.) The exiting material is then cut

into desired lengths. Typical products made by pultrusion (which may contain up to

about 75% reinforcing fiber) are golf clubs, ski poles, fishing poles, driveshafts, and

such structural members as ladders, walkways, and handrails. Cross sections as

large as 1.5 m >< 0.3 m have been made by this process.

Pulforming. Continuously reinforced products other than those with constant

cross-sectional profiles are made by pulforming. After being pulled through the

polymer bath, the composite is clamped between the two halves of a die and cured

into a finished product. The dies recirculate and shape the products successively.

Commonly made products are hammer handles reinforced by glass fibers and

curved automotive leaf springs.

EXAMPLE l9.3 Polymer Automotive-body Panels Shaped by Various Processes

Polymeric materials are commonly used for automobile Typical examples of parts made for

bodies; this example outlines typical applications of automobiles are (a) body panels and other large

polymers. Three commonly used and competing exterior components made by injection molding;

processing methods are (a) injection-molding of (b) front fenders and rear quarter panels made of

thermoplastics and elastomers; (b) reaction- polyphenylene-ether/ nylon or thermoplastric polyester;

injection molding of polyurea/polyurethanes; and (c) outer door panels made of polycarbonate/ ABS; and

(c) compression-molding of sheet-molding compound (d) fascias made of thermoplastic polyolefin. These

(SMC) with resin-transfer-molded polyester and materials are selected for design flexibility, impact

vinylester. strength and toughness, corrosion resistance, high